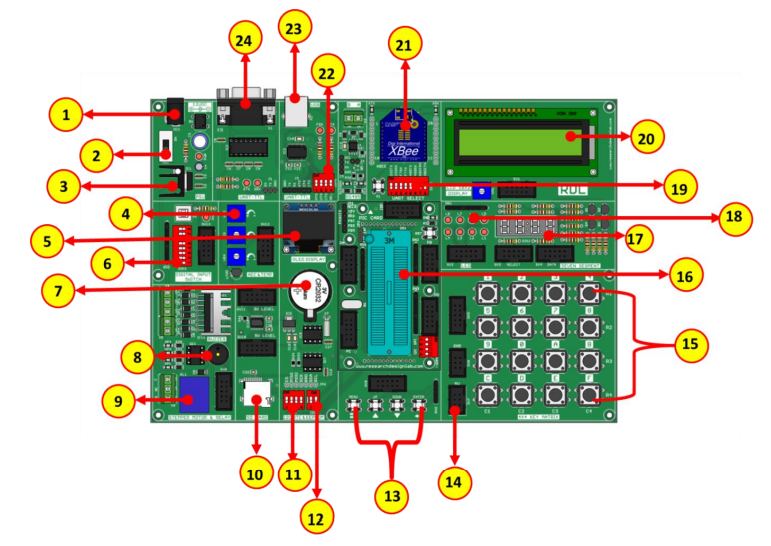

PIC Board Narration

2. Power ON Switch

3. Heat Sink

4. ADC (Variable Resistor POT)

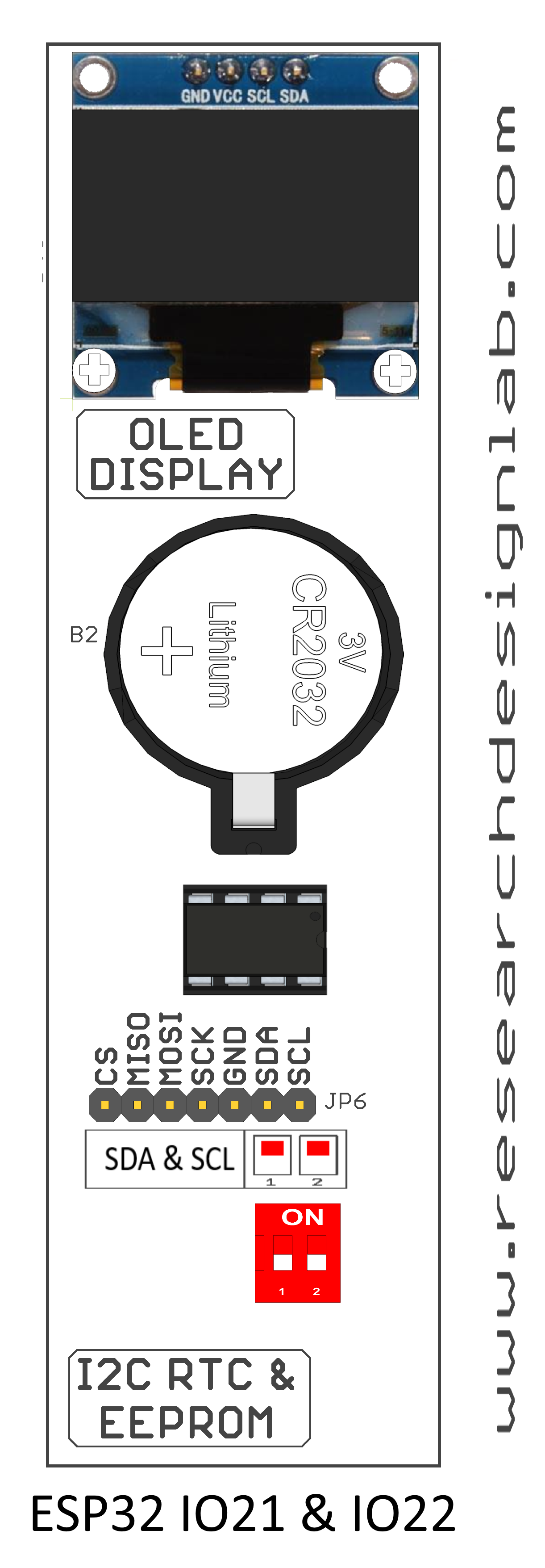

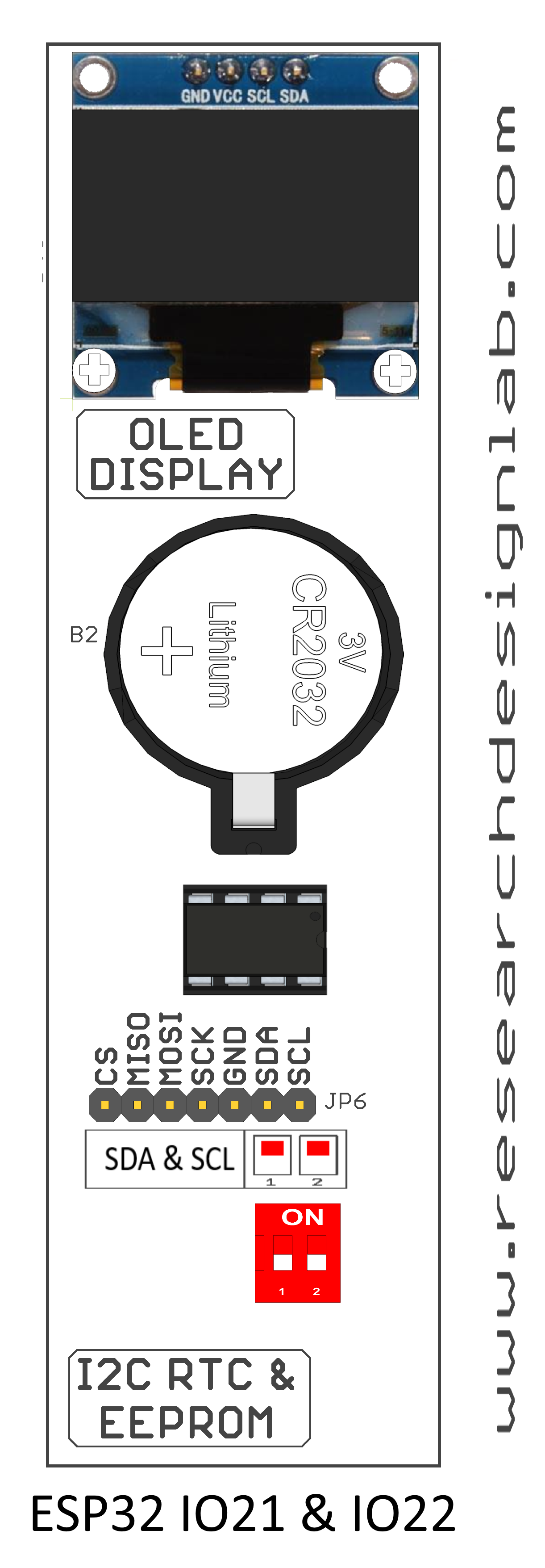

5. OLED Display

6. Digital Input Switch

7. RTC Battery

8. Buzzer

9. Relay

10. SD Card Holder

11. Jumper Settings for I2C RTC

12. Jumper Settings for EEPROM

14. RDL Bus FRC Connector

15. Keypad Matrix

16. PIC Controller

17. 7 Segment Display

18. 2*4 LED's

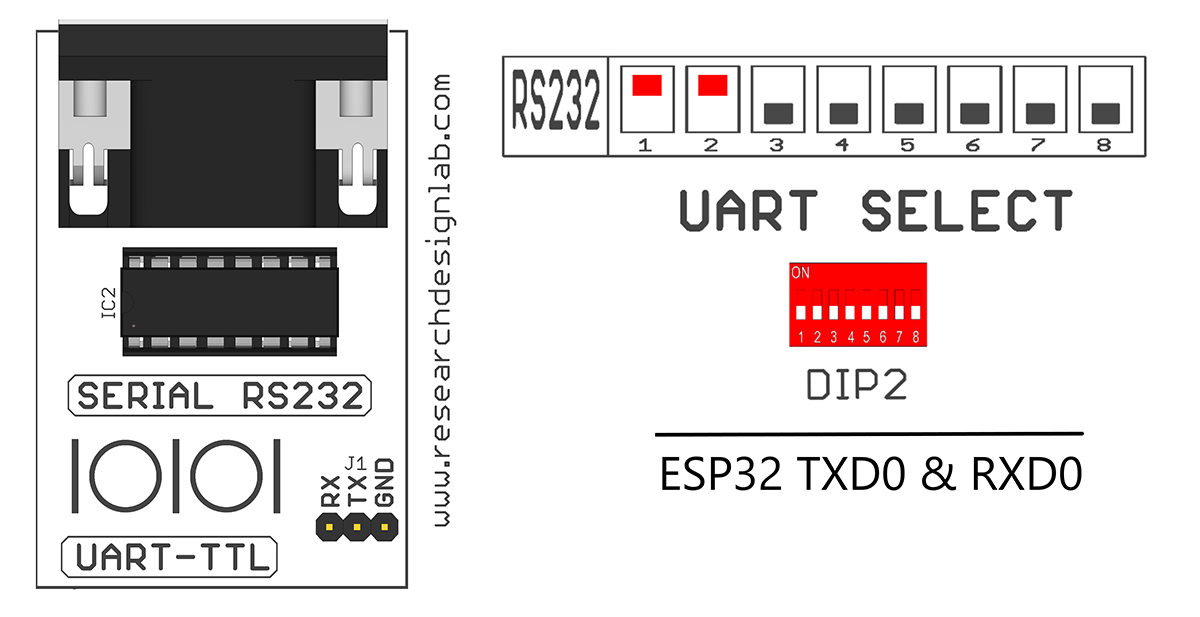

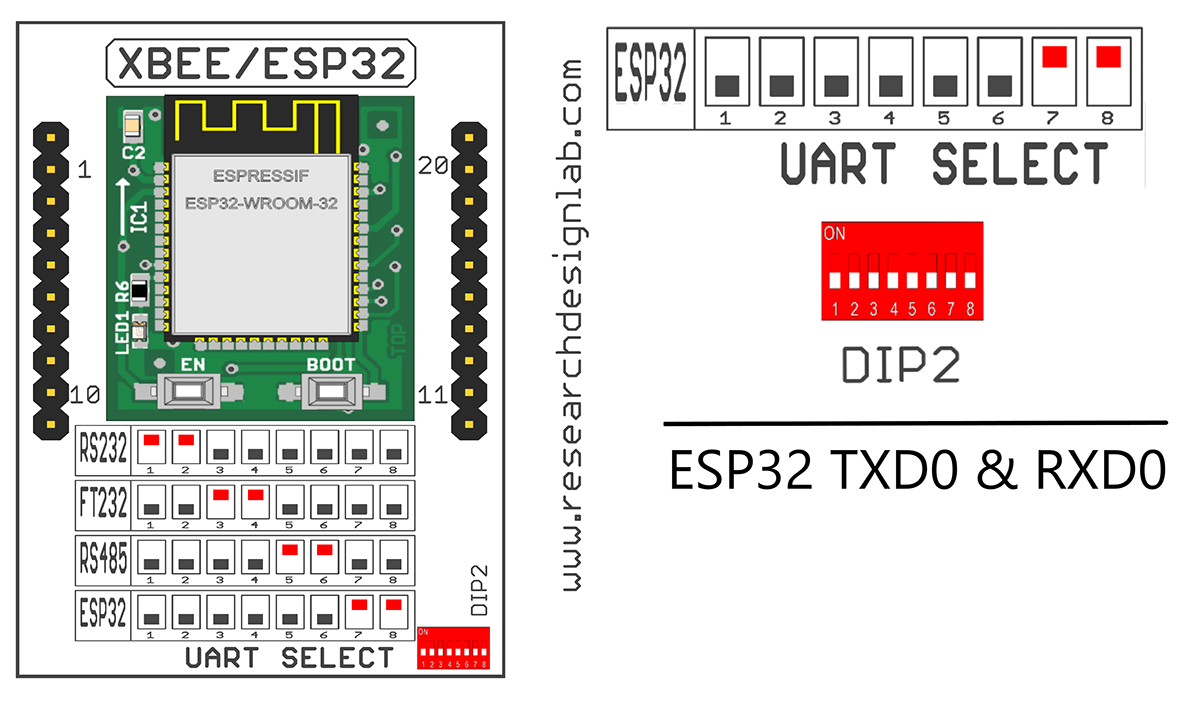

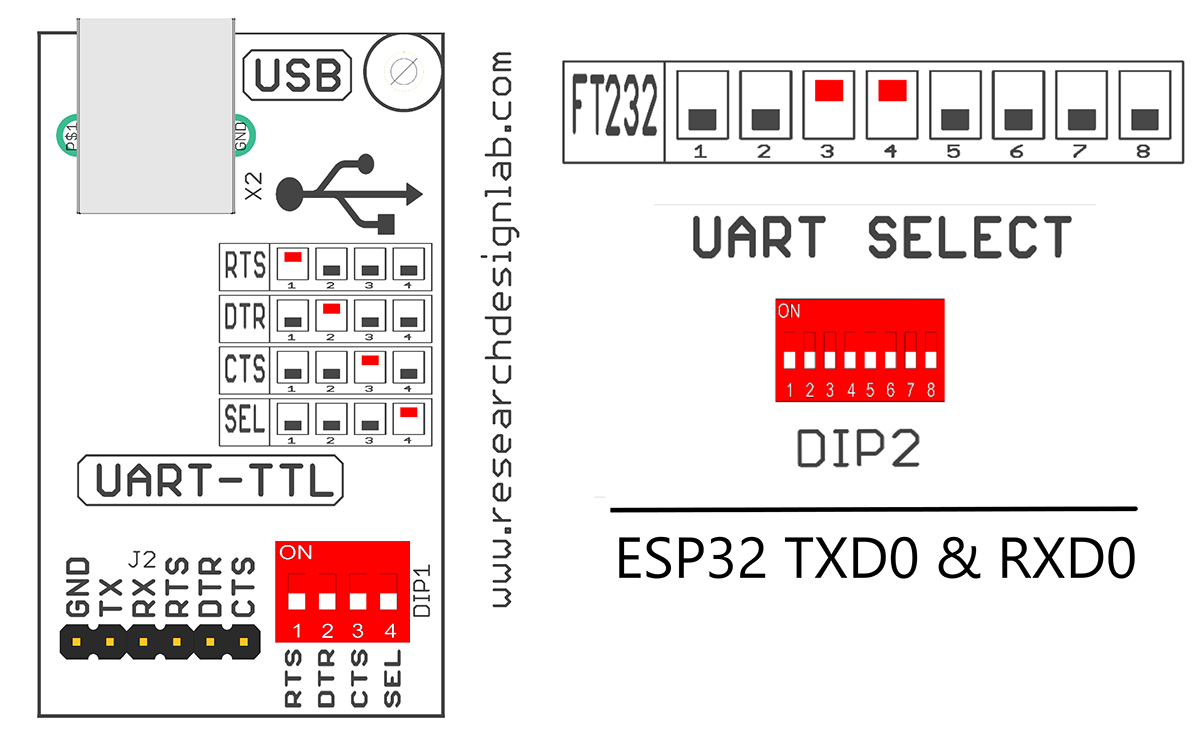

19. Jumper Settings for UART Selection Pin

20. 16*2 LCD Display

21. WiFi Module

22. Jumper Settings for UART TTL

23. USB Port

24. DB-9 Serial Female Connector

Application:

- Light sensing & controlling devices

- Temperature sensing and controlling devices

- Fire detection & safety devices

- Industrial instrumentation devices

- Application of microcontroller in Industrial Control Devices

- Process Control Devices

- Industrial instrumentation devices

- IoT Applications

- Automation Applications

Package Includes:

- Development Board with Wooden Enclosure

- USB Cable

- 12V 2A Adapter.

- FRC Cable

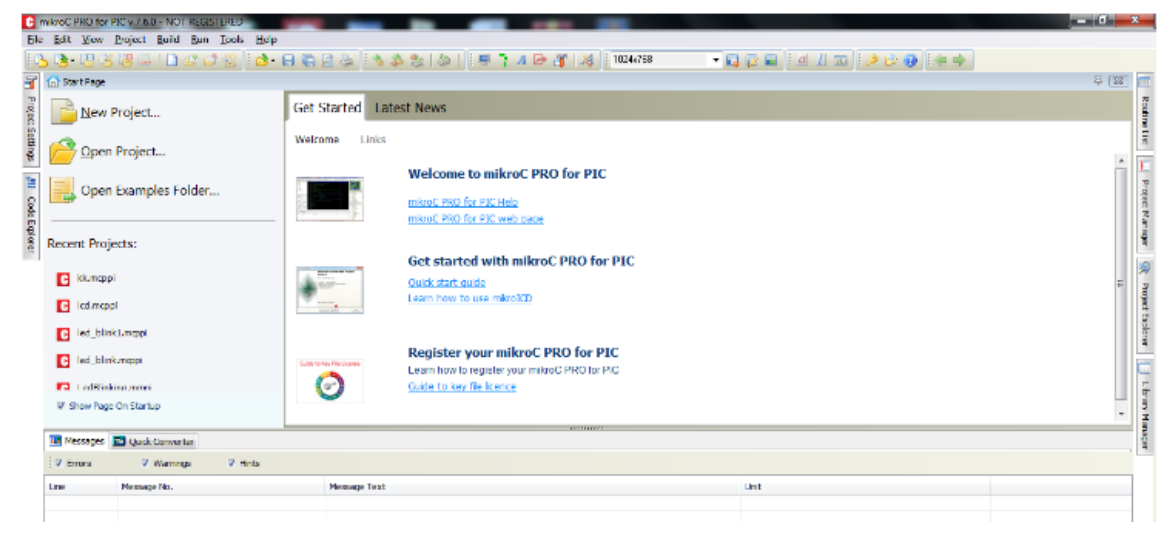

MikroC PRO for PIC

Download and install the MikroC PRO for PIC,CLICK HERE.

MikroC PRO for PIC

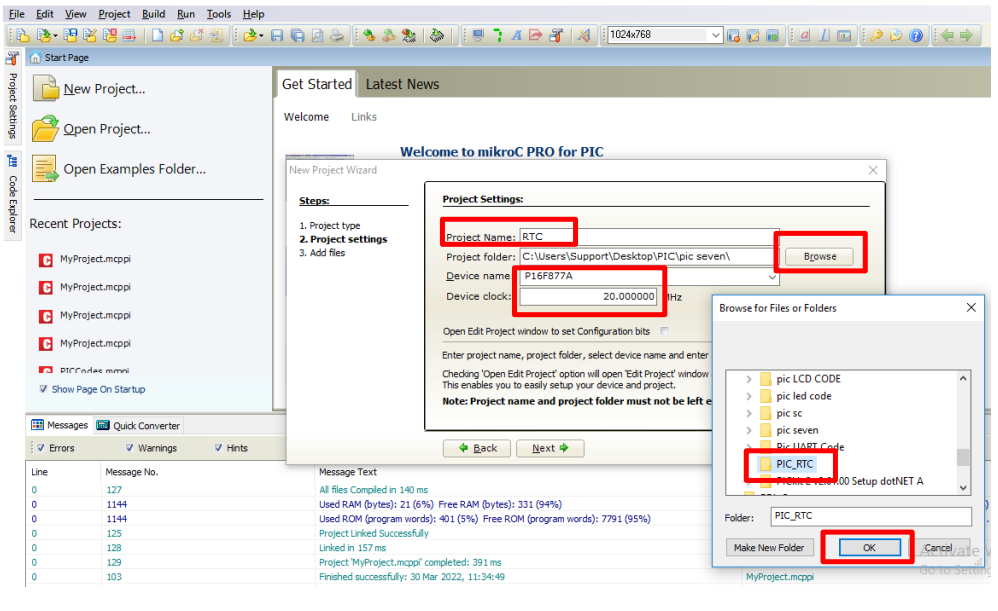

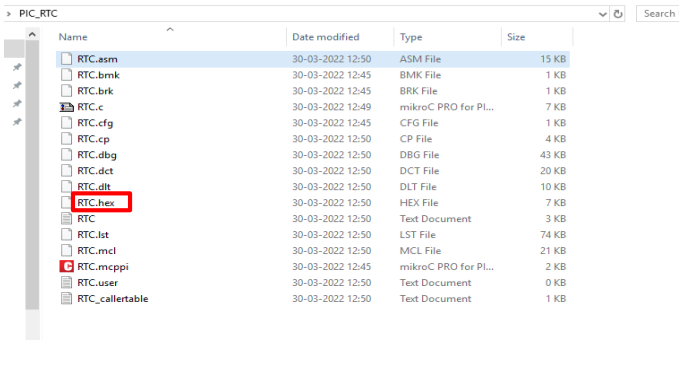

Create a New Folder (Ex:PIC_RTC)

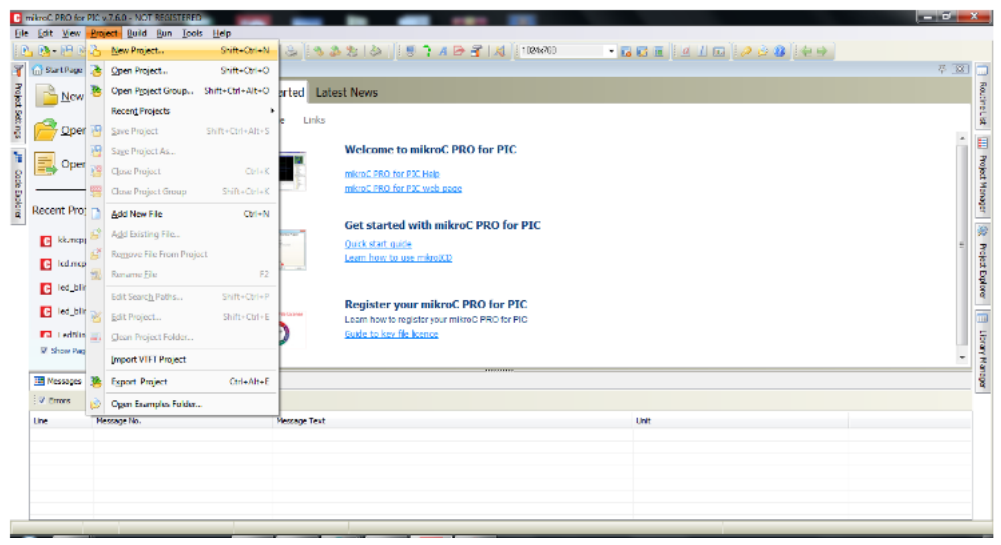

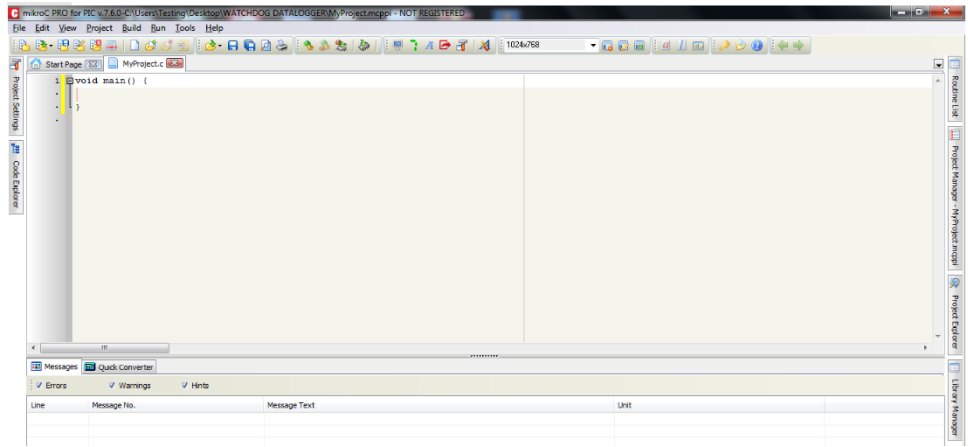

Step1: Open the MikroC PRO software and once the MikroC compiler started, you will see a screen as shown below.

Step2: Create a New Project from the menu bar by going to Project >> New Project.

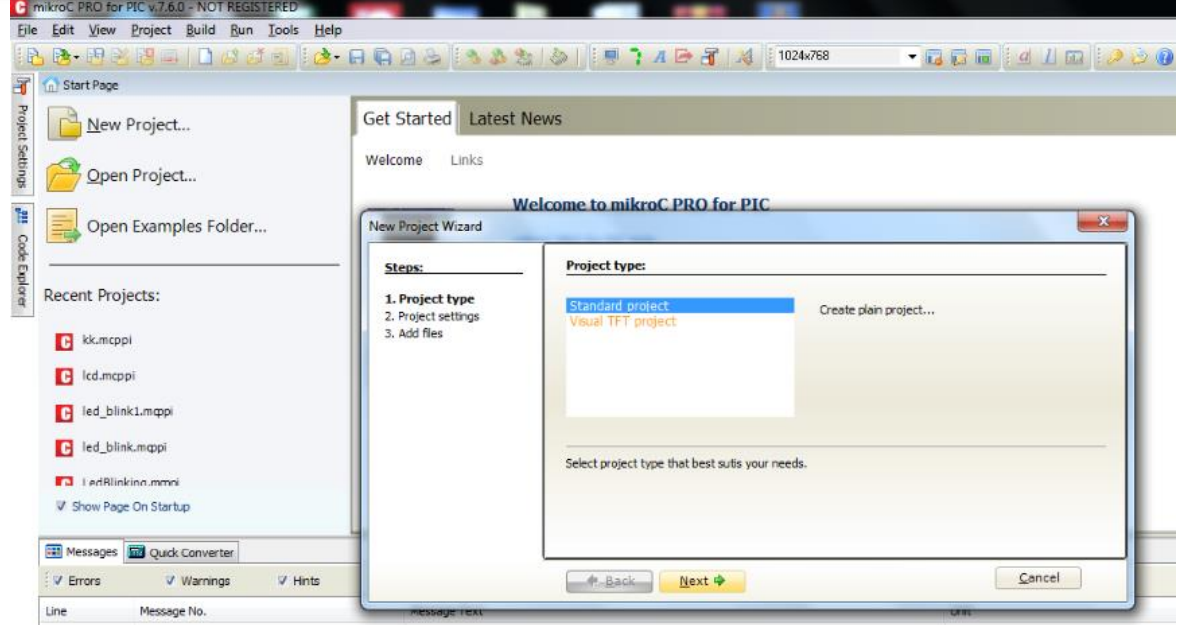

Step3: “New Project Wizard” window opens. Select a Standard project and click Next.

Step4: Type Project Name (Ex:RTC),Browse the Folder which you have already created to save your project(Ex:PIC_RTC), PIC Microcontroller device is P18F877A and Device clock (set it to 20MHz). Then click Next.

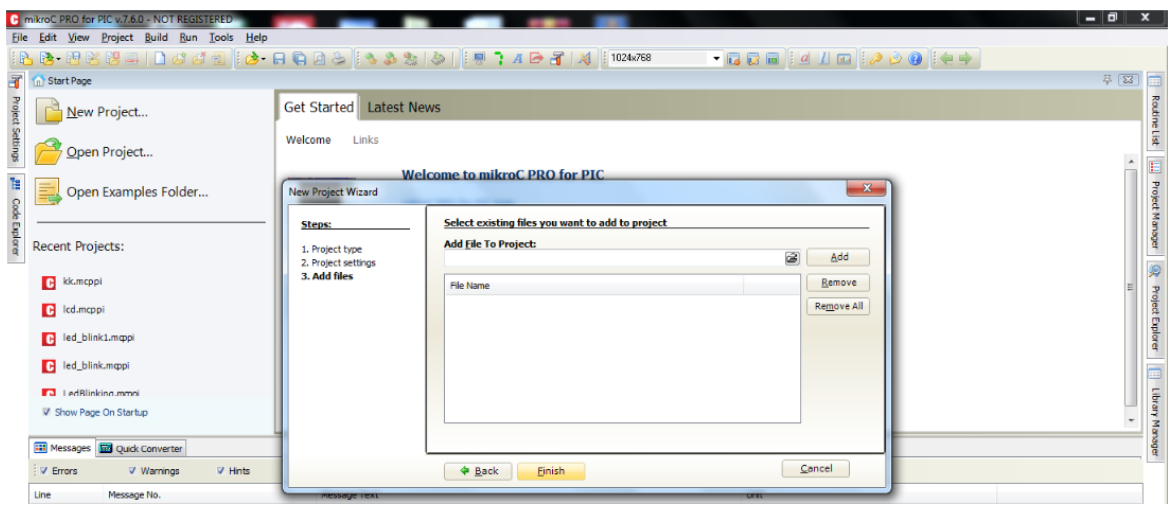

Step5: Click on Finish.

Step6: A window shown below appears. Write your program.

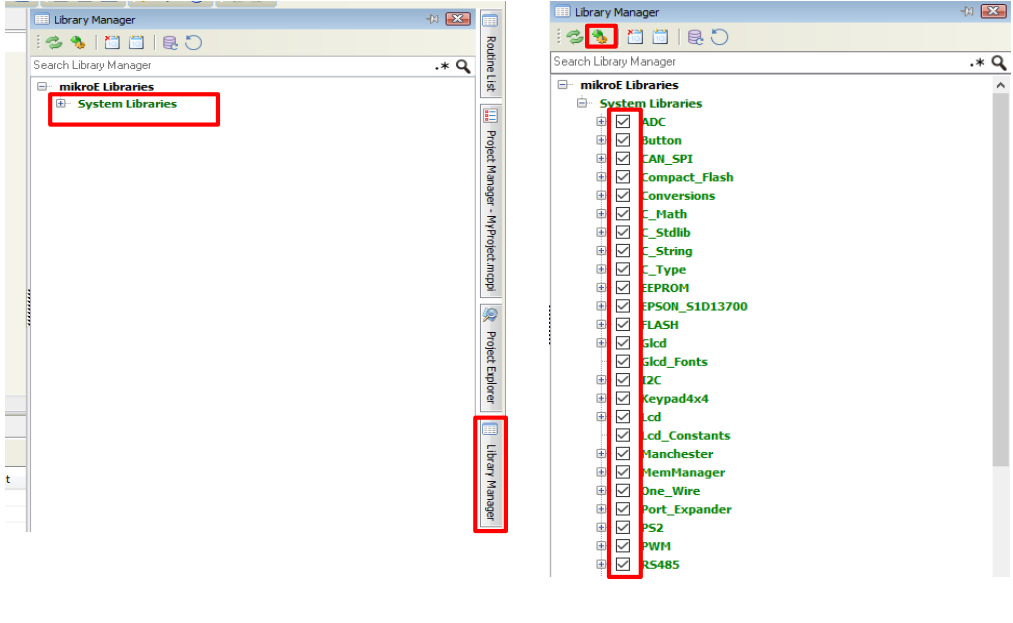

Step7: Click on System Libraries and select the required libraries/all the libraries from the list and click on rebuild libraries.

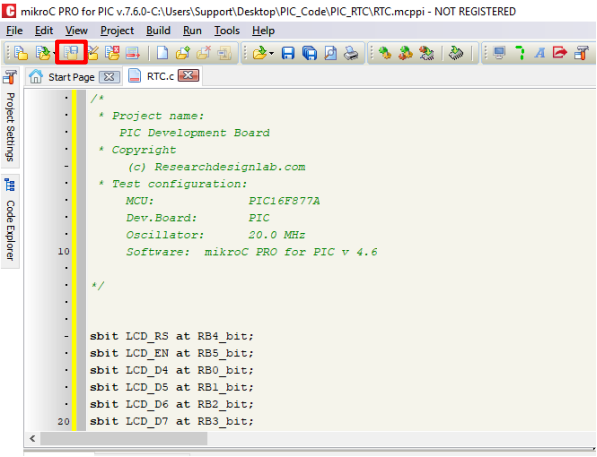

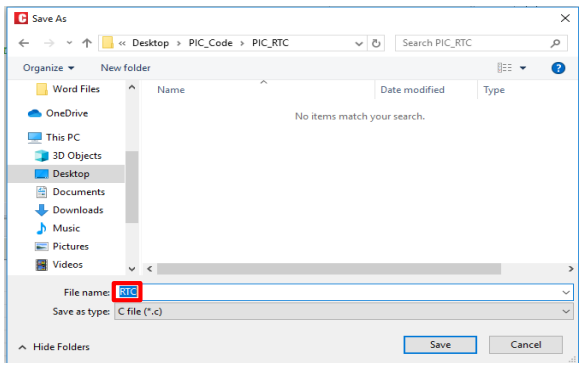

Step8: We have given RTC Example Code below.Click on Save and give the file name (Ex:RTC) and save it in the Project folder which was created before (Ex:PIC_RTC).

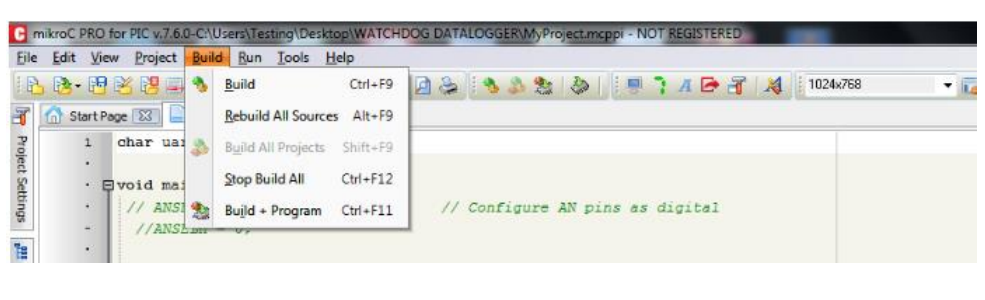

Compile Code with MikroC

Step9: After Saving the code,Click on Build from Menu bar. If everything is right it will display a message of finish successfully in the below window.

Step10: After that go to the project folder(Ex:PIC_RTC) where you saved your project and locate the hex file. Because we will use this hex file to program Pic Microcontroller.

Installation of PicKit2

For download & installing Pickit2 Software,CLICK HERE.

Uploading Hex File Using Pickit2

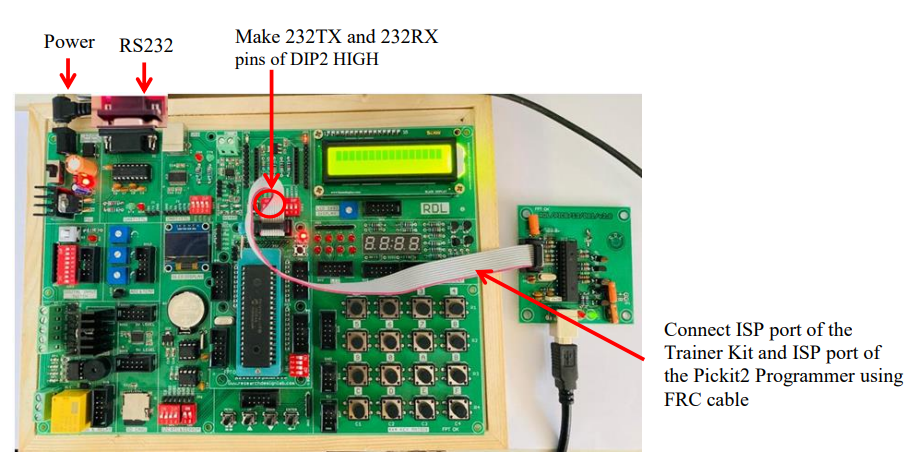

NOTE:

Before Uploading any hex file to the Trainer Kit, make the below settings

1. Make FTRX and FTTX pins of DIP2 HIGH

2. Make all pins of DIP1 HIGH

For Pickit2 User Guide,CLICK HERE (Refer till Page 16 to load the hex file to the development Board).

Blinking an LED

Aim:Interfacing LED’s with PIC-Microcontroller.

Description:Turning ON and OFF an LED’s after Particular delay.

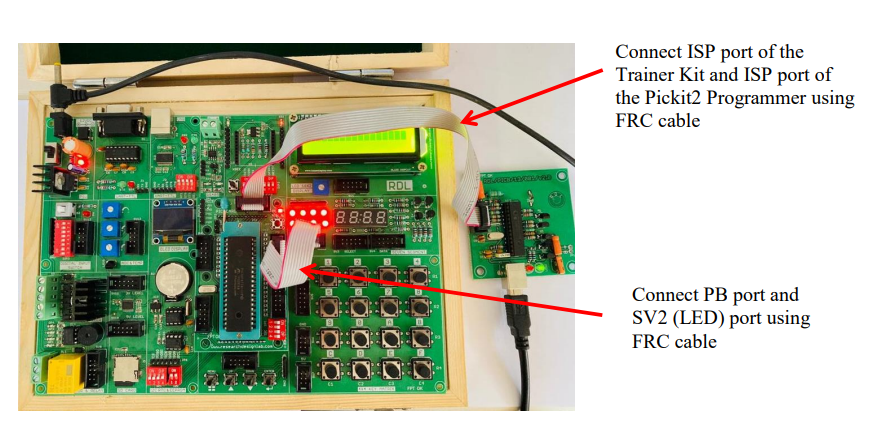

Hardware Requirement: PIC Trainer Kit, Pickit2 Programmer,FRC cables,USB A to B cable and 12V 2A Adapter.

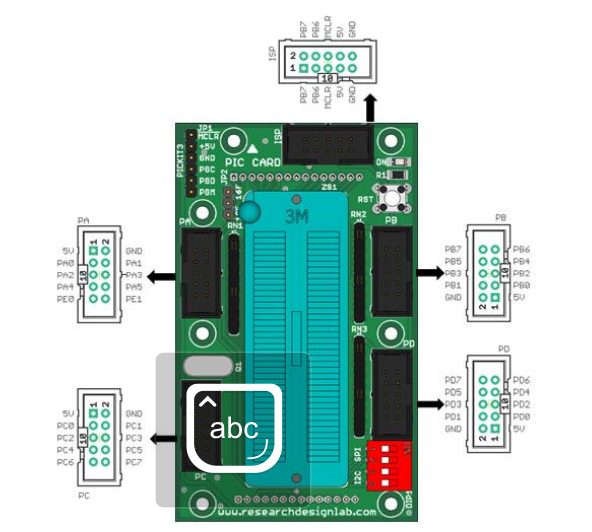

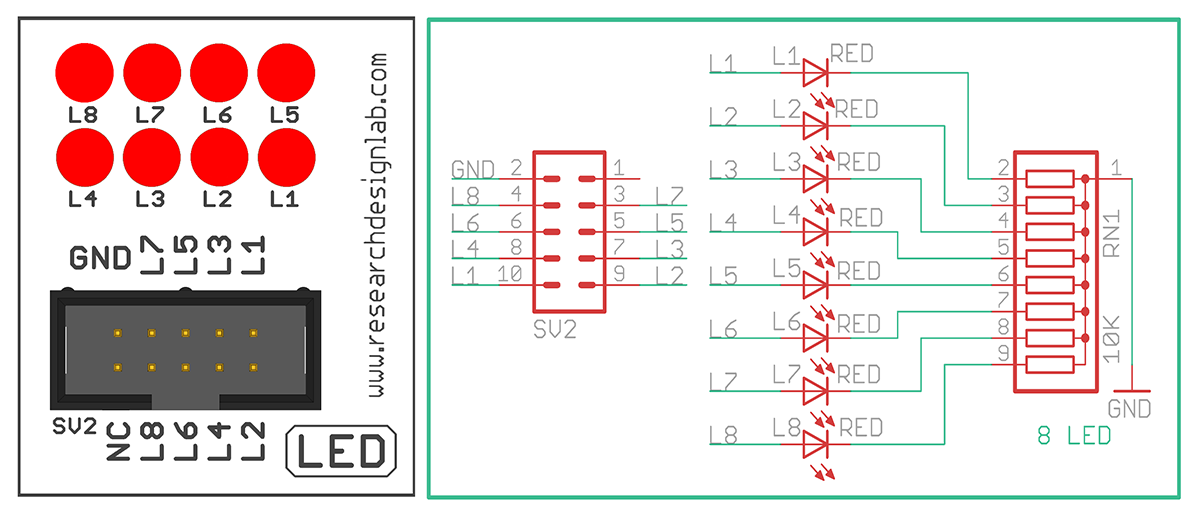

Schematic Diagram

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC cable.

2. Connect PB port and SV2 (LED) port using FRC cable as shown above.

3. Connect the USB cable to the programmer and connect the Power Adapter to the PIC Trainer Kit.

4.Open MikroC Pro,write the program.Then click on Build to verify the code.

5. Click the radio button ISP by Com Port, Select the Com Port.

6. Open Pickit2 Software to upload the hex File (Follow the steps given in the Pickit2 User Guide).

7. Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller and you can see the LED blink.

Code

/*

* Project name:

PIC Development Board LED and Keypad code

* Copyright

(c) Researchdesignlab.com

* Test configuration:

MCU: PIC16F877A

Dev.Board: PIC

Oscillator: 20.0 MHz

Software: mikroC PRO for PIC v 4.6

Developer: DD

*/

sbit LED1 at RB0_bit; //defining PortB Pin B0 as LED1

sbit LED2 at RB1_bit; //defining PortB Pin B1 as LED2

sbit LED3 at RB4_bit; //defining PortB Pin B4 as LED3

sbit LED4 at RB5_bit; //defining PortB Pin B5 as LED4

void main()

{

TRISB=0x00; //defining PORTB as output port

PORTB= 0XFF;

Delay_ms(1000);

PORTB= 0X00;

Delay_ms(1000);

while(1)

{

PORTB=0xFF; //binary equivalent value:00000000

Delay_ms(1000);

PORTB=0x00; //binary equivalent value:11111111

Delay_ms(1000);

}

}

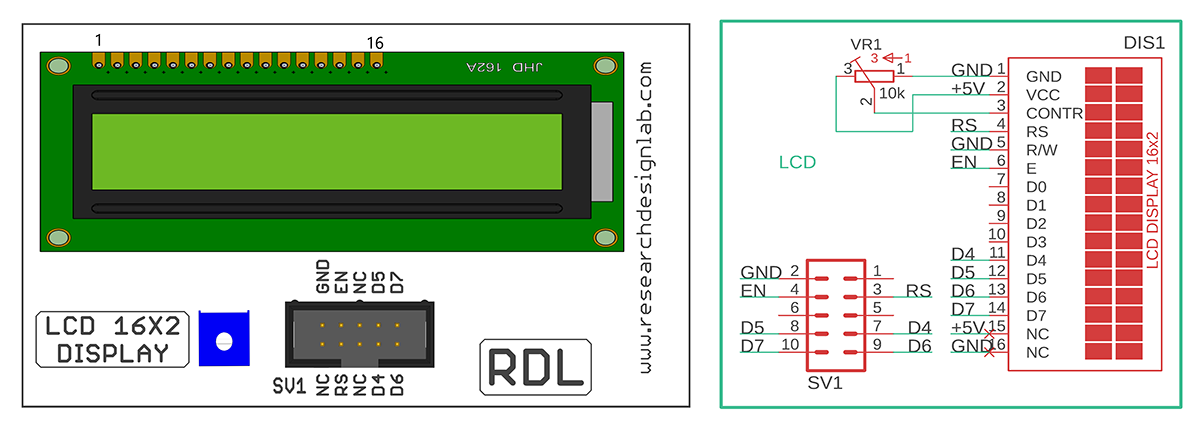

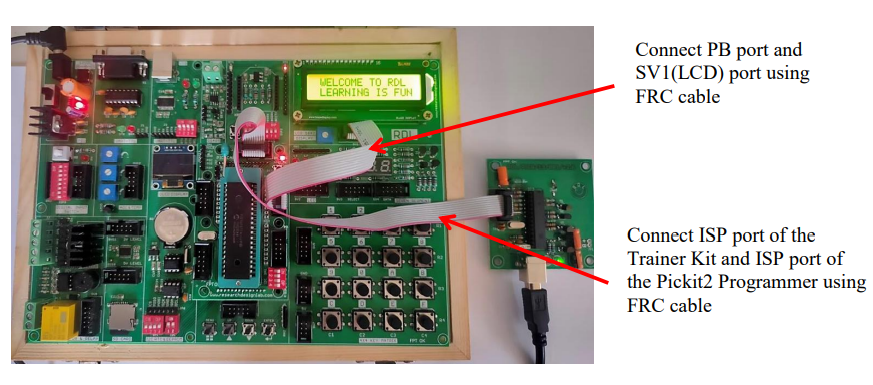

Liquid Crystal Display

Aim:Interfacing LCD Display with PIC-Microcontroller.

Description:To display the message on the LCD screen.

Hardware Requirement: PIC Trainer Kit, Pikit2 Programmer, FRC cables,USB A to B cable and 12V 2A Power Adapter.

Schematic Diagram

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC cable.

2. Connect PB port and SV1 (LCD 16*2 Display) port using FRC cable as shown above.

3. Connect the USB cable to the programmer and connect the Power Adapter to the PIC Trainer Kit.

4.Open MikroC Pro,write the program to display the message in the LCD.Then click on

Build to verify the code.

5. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

6. Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller

and you can see the message displayed on the LCD.

Code

sbit LCD_RS at RB0_bit; //defining PortB Pin B0 as LCD_RS

sbit LCD_EN at RB1_bit; //defining PortB Pin B1 as LCD_EN

sbit LCD_D4 at RB4_bit; //defining PortB Pin B4 as LCD_D4

sbit LCD_D5 at RB5_bit; //defining PortB Pin B5 as LCD_D5

sbit LCD_D6 at RB6_bit; //defining PortB Pin B6 as LCD_D6

sbit LCD_D7 at RB7_bit; //defining PortB Pin B7 as LCD_D7

sbit LCD_RS_Direction at TRISB0_bit;

sbit LCD_EN_Direction at TRISB1_bit;

sbit LCD_D4_Direction at TRISB4_bit;

sbit LCD_D5_Direction at TRISB5_bit;

sbit LCD_D6_Direction at TRISB6_bit;

sbit LCD_D7_Direction at TRISB7_bit;

// End LCD module connections

char uart_rd;

void main() {

TRISB6_bit=0;

UART1_Init(9600); // Initialize UART module at 9600 bps

Delay_ms(10);

// Wait for UART module to stabilize

Lcd_Init();

UART1_Write_Text("Start");

UART1_Write(10);

UART1_Write(13);

Delay_ms(10);

Lcd_Cmd(_LCD_CLEAR); // Clear display

Lcd_Cmd(_LCD_CURSOR_OFF); // Cursor off

Lcd_Out(1,2,"WELCOME TO RDL");

Lcd_Out(2,2,"LEARNING IS FUN");

while (1);

}

// Endless loop

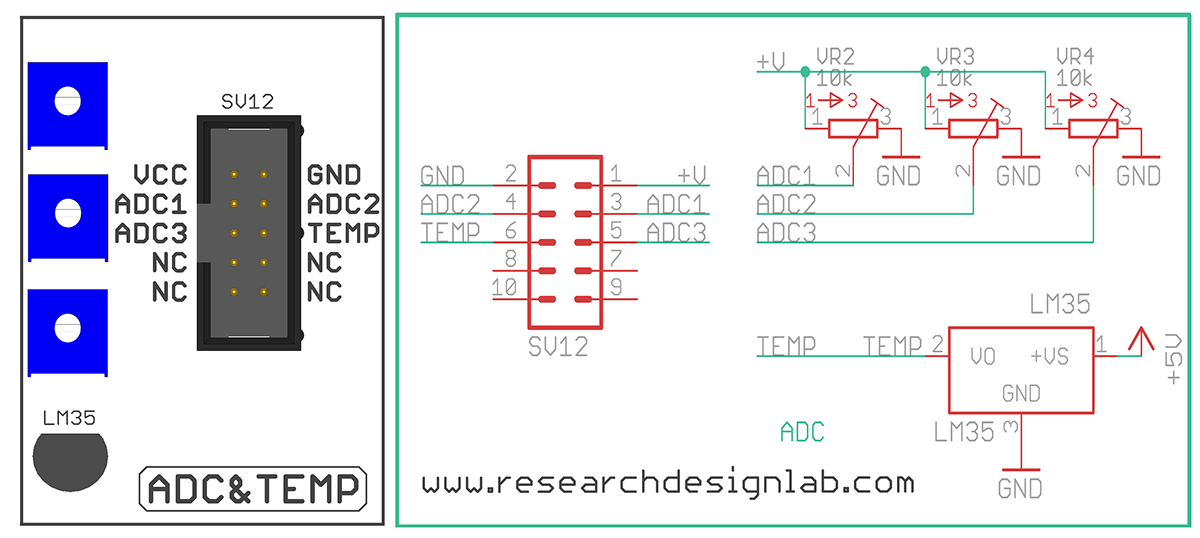

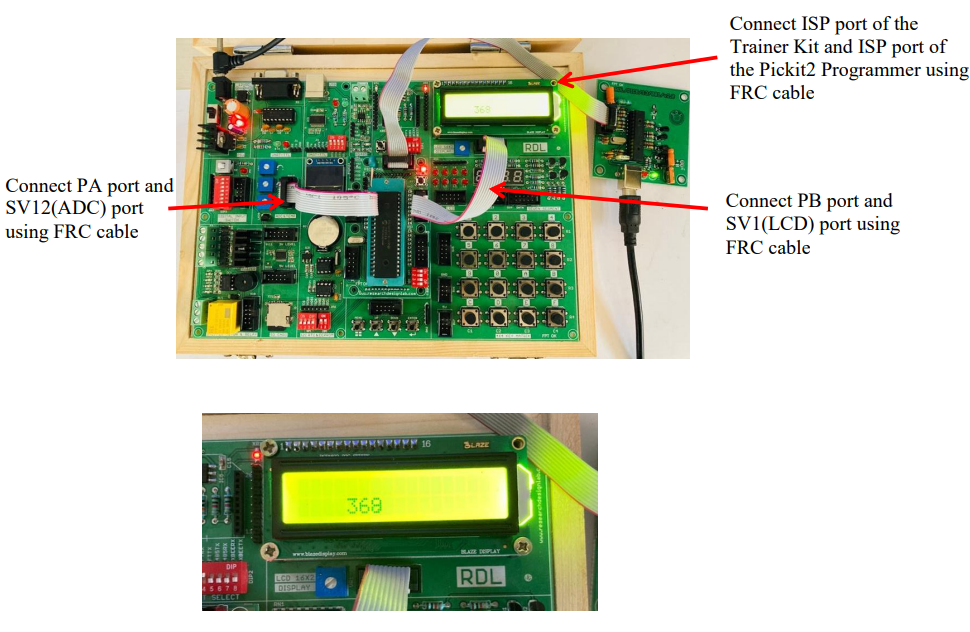

ADC

Aim:Interfacing ADC with PIC-Microcontroller.

Description:To learn how to read ADC Values and display the values in the LCD

Hardware Requirement: PIC Trainer Kit, Pikit2 Programmer, FRC cables,USB A to B cable and 12V 2A Power Adapter.

Schematic Diagram

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC

cable.

2. Connect PB port and SV1 (LCD 16*2 Display) port using FRC cable as shown above.

3. Connect PA port and SV12 (ADC) port using FRC cable.

4.Connect the USB cable to the programmer and connect the Power Adapter to the PIC

Trainer Kit.

5. Open MikroC Pro,write the program.Then click on Build to verify the code.

6. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User

Guide)

7.Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller

and Vary the POT to see the Analog Values displayed on the LCD.

Code

/*

* Project name:

PIC Development Board

* Copyright

(c) Researchdesignlab.com

* Test configuration:

MCU: PIC16F877A

Dev.Board: PIC

Oscillator: 20.0 MHz

Software: mikroC PRO for PIC v 4.6

*/

// LCD module connections

sbit LCD_RS at RB0_bit;

sbit LCD_EN at RB1_bit;

sbit LCD_D4 at RB4_bit;

sbit LCD_D5 at RB5_bit;

sbit LCD_D6 at RB6_bit;

sbit LCD_D7 at RB7_bit;

sbit LCD_RS_Direction at TRISB0_bit;

sbit LCD_EN_Direction at TRISB1_bit;

sbit LCD_D4_Direction at TRISB4_bit;

sbit LCD_D5_Direction at TRISB5_bit;

sbit LCD_D6_Direction at TRISB6_bit;

sbit LCD_D7_Direction at TRISB7_bit;

// End LCD module connections

char txt[6];

unsigned tmp;

void main() {

Lcd_Init(); // Initialize LCD

Lcd_Cmd(_LCD_CLEAR); // Clear display

Lcd_Cmd(_LCD_CURSOR_OFF); // Cursor off

Lcd_Out(1, 1, "PIC DVLPMNT BRD"); // Write text on Lcd starting from

Delay_ms(1000); // 1000ms delay

row 1, column 3:

while(1)

{ // read analog value from ADC

module channel 0

tmp = ADC_Read(0); // calulting for temp

tmp=((tmp/1023.0)*500); // Clear display

wordToStr(tmp, txt); //convaersion wrd to str

Lcd_Cmd(_LCD_CLEAR); // Clear display

Lcd_Out(2, 3, txt); // Write text on Lcd starting from

row 2, column 3:

Delay_ms(500); // 500ms delay

}

}

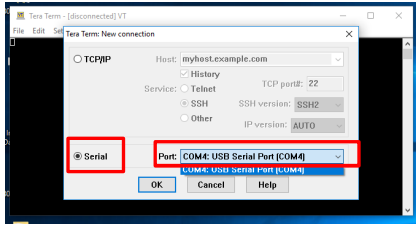

UART

Aim:Interfacing UART with PIC-Microcontroller.

Description: Transmit / Receive Data using UART and display the data’s on the terminal Software.

Hardware Requirement: PIC Trainer Kit, PicKit2 Programmer, USB to RS232 Converter, USB A to B Cable and 12V 2A Power Adapter.

Schematic Diagram

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC

cable.

2. Connect the 12V 2A Power Adapter to the PIC Trainer Kit Board.

3. Open MikroC Pro,write the program. Then click on Build to verify the code.

4.Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

5. Once the hex file is written successfully,press the reset switch of the PIC Microcontroller

6. Remove the USB cable from the Board.

7. Connect the USB to RS232 converter to the Board and other side of the connector to the

Computer/PC using USB Cable.

8. Make 232TX and 232RX pins of DIP2 HIGH

9. Open any of the Terminal Software to check the output

(Ex: Tera Term Software ,To Download this Software, CLICK HERE )

Open the Tera Term Software,Click on the radio button Serial and select the Port and then click on OK.

10. Press the Reset Button of the PIC Microcontroller, You can see the data on the terminal

software.

10. Press the Reset Button of the PIC Microcontroller, You can see the data on the terminal

software.

11. Send the data from your keyboard, everything you type should be displayed in the

terminal window.

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC cable.

2. Connect the 12V 2A Power Adapter to the PIC Trainer Kit Board.

3. Open MikroC Pro,write the program. Then click on Build to verify the code.

4.Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

5. Once the hex file is written successfully,press the reset switch of the PIC Microcontroller

6. Remove the USB cable from the Board.

Code

char uart_rd;

void main() {

UART1_Init(9600); // Initialize UART module at 9600 bps

Delay_ms(100); // Wait for UART module to stabilize

UART1_Write_Text("RDL");

UART1_Write(10);

UART1_Write(13);

while (1) { // Endless loop

if (UART1_Data_Ready()) { // If data is received,

uart_rd = UART1_Read(); // read the received data,

UART1_Write(uart_rd); // and send data via UART

}

}

}

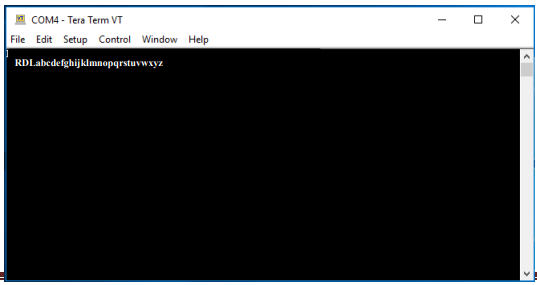

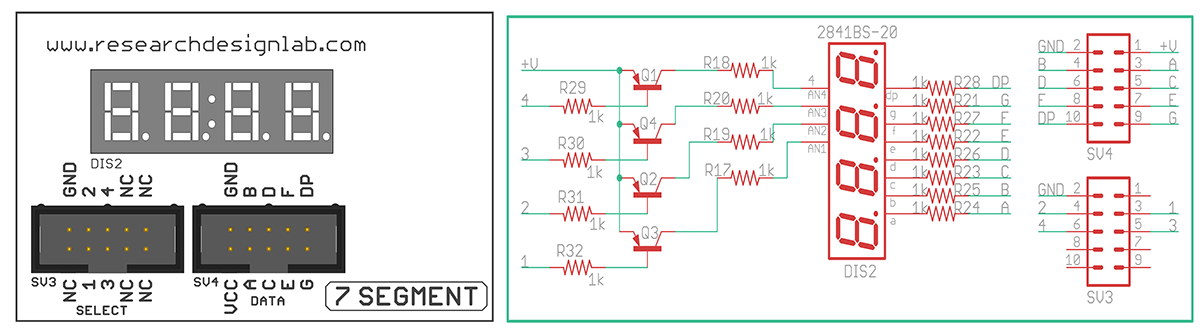

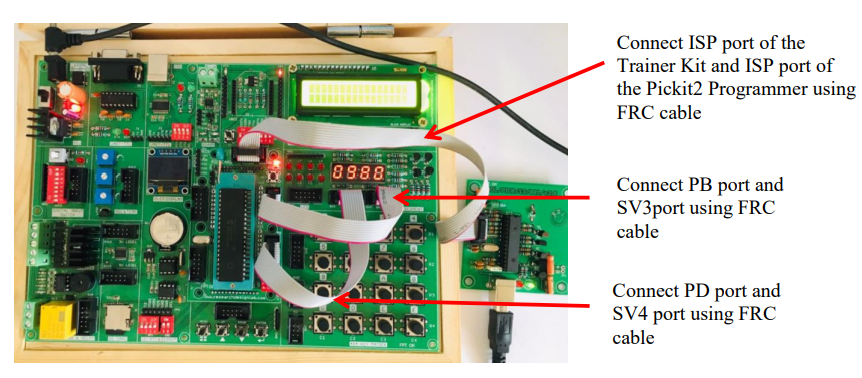

Seven Segment Display

Aim: Interfacing Seven Segment Display with 8051-Microcontroller.

Description: To display numbers in the seven segment.

Hardware Requirement: 8051 Trainer Kit, FRC cables and USB A to B cable.

Schematic Diagram

Procedure:

1. Connect ISP port of the Trainer Kit and ISP port of the Pickit2 Programmer using FRC

cable.

2. Connect PB port and SV4 port and Connect PD port and SV3 port using FRC cable as shown above

3. Connect the USB cable to the programmer and connect the 12V 2A Power Adapter to the PIC Trainer Kit.

4. Open MikroC Pro,write the program.Then click on Build to verify the code.

5. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

6. Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller and you can see the numbers displayed on the Seven Segment Display.

Code

/*

* Project name:

PIC Development Board

* Copyright

(c) Researchdesignlab.com

* Test configuration:

MCU: PIC16F877A

Dev.Board: PIC

Oscillator: 20.0 MHz

Software: mikroC PRO for PIC v 4.6

*/

unsigned int portb_index,portb_array[4],digit, COUNT=0;

unsigned short mask(unsigned short num) {

switch (num) {

case 0 : return 0xC0;

case 1 : return 0xF9;

case 2 : return 0xA4;

case 3 : return 0xB0;

case 4 : return 0x99;

case 5 : return 0x92;

case 6 : return 0x82;

case 7 : return 0xF8;

case 8 : return 0x80;

case 9 : return 0x90;

} //case end

}

void interrupt() {

PORTD = 0XFF; // Turn off all 7seg displays

PORTB= portb_array[portb_index]; // bring appropriate value to PORTB

if(portb_index==0)

PORTD = 0XF7;

else if(portb_index==1) // turn on appropriate 7seg. display

PORTD = 0XFB;

else if(portb_index==2) // turn on appropriate 7seg. display

PORTD = 0XFD;

else if(portb_index==3) // turn on appropriate 7seg. display

PORTD = 0XFE;

// increment portd_index

portb_index++ ;

if (portb_index > 4u)

portb_index = 0; // turn on 1st, turn off 2nd 7seg.

TMR0 = 0; // reset TIMER0 value

INTCON = 0x20; // Clear T0IF

}

void display(unsigned int number)

{

digit = number / 1000u ; // extract thousands digit

portb_array[3] = mask(digit); // and store it to PORTB array

digit = (number / 100u) % 10u; // extract hundreds digit

portb_array[2] = mask(digit); // and store it to PORTB array

digit = (number / 10u) % 10u; // extract tens digit

portb_array[1] = mask(digit); // and store it to PORTB array

digit = number % 10u; // extract ones digit

portb_array[0] = mask(digit); // and store it to PORTB array

}

void main() {

TRISD=0X00;

TRISB=0X00;

OPTION_REG = 0x80; // Timer0 settings

digit = 0;

portb_index = 0;

TMR0 = 0;

INTCON = 0xA0; // Enable GIE, T0IE

PORTD = 0xFF;

Delay_ms(200);

COUNT=0;

while(1)

{

display(COUNT);

Delay_ms(300);

COUNT=COUNT+5;

if(COUNT>2000)

COUNT=0;

}

}

RTC (Real Time Clock)

Aim:Interfacing Real Time Clock with PIC-Microcontroller.

Description:To display Date and Time on the LCD Display using PIC Trainer Kit.

Hardware Requirement: PIC Trainer Kit, PicKit2 Programmer, FRC Cables, USB A to B Cable and 12V 2A Power Adapter.

Schematic Diagram

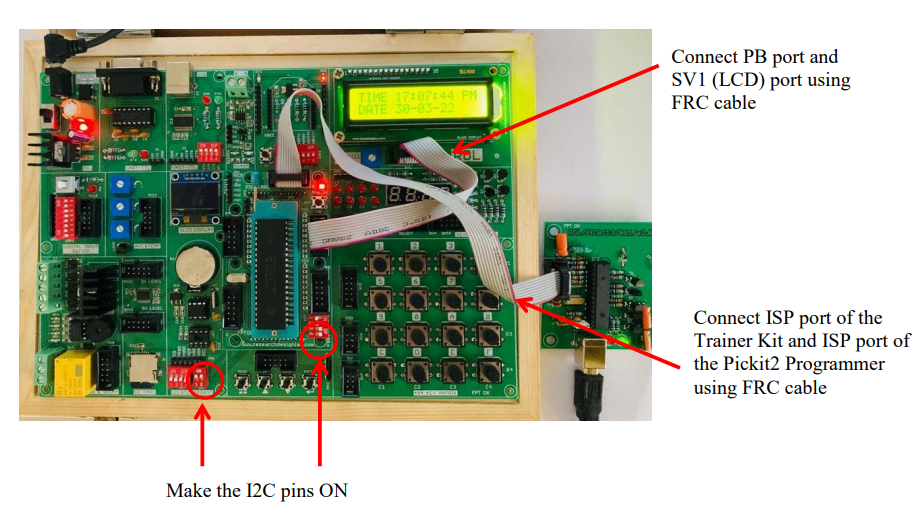

Procedure:

1. Connect ISP port of the Trainer Kit and ISP port of the Pickit2 Programmer using FRC cable.

2. Connect PB port and SV1 port using FRC cable as shown above

3. Connect the USB cable to the programmer and connect the 12V 2A Power Adapter to the PIC Trainer Kit.

4. Open MikroC Pro,write the program.Then click on Build to verify the code.

5. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

6. Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller and the Date and Time will be displayed on the LCD Display.

Code

// Software I2C connections

sbit Soft_I2C_Scl at RC4_bit;

sbit Soft_I2C_Sda at RC3_bit;

sbit Soft_I2C_Scl_Direction at TRISC4_bit;

sbit Soft_I2C_Sda_Direction at TRISC3_bit;

// End Software I2C connections

// LCD module connections

sbit LCD_RS at RB0_bit;

sbit LCD_EN at RB1_bit;

sbit LCD_D4 at RB4_bit;

sbit LCD_D5 at RB5_bit;

sbit LCD_D6 at RB6_bit;

sbit LCD_D7 at RB7_bit;

sbit LCD_RS_Direction at TRISB0_bit;

sbit LCD_EN_Direction at TRISB1_bit;

sbit LCD_D4_Direction at TRISB4_bit;

sbit LCD_D5_Direction at TRISB5_bit;

sbit LCD_D6_Direction at TRISB6_bit;

sbit LCD_D7_Direction at TRISB7_bit;

// End LCD module connections

void delay()

{

unsigned char z;

for(z=250;z>z--)

;

}

void rtc_init()

{

unsigned char

a[]={0x00,0x00,0x01,0x05,0x02,0x17,0x03,0x05,0x04,0x30,0x05,0x03,0x06,0x22};

unsigned char x=0;

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(a[0]);

Soft_I2C_Write(a[1]);

Soft_I2C_Stop();

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(a[2]);

Soft_I2C_Write(a[3]);

Soft_I2C_Stop();

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(a[4]);

Soft_I2C_Write(a[5]);

Soft_I2C_Stop();

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(a[8]);

Soft_I2C_Write(a[9]);

Soft_I2C_Stop();

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(a[10]);

Soft_I2C_Write(a[11]);

Soft_I2C_Stop();

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(a[12]);

Soft_I2C_Write(a[13]);

Soft_I2C_Stop();

}

void display(unsigned char a1)

{

unsigned char b1;

b1=(a1 & 0x0f0);

b1=(b1>>4)+0x30;

Lcd_Chr_Cp(b1);

b1=(a1 & 0x0f);

b1=b1+0x30;

Lcd_Chr_Cp(b1);

}

void main()

{

unsigned char i,temp,ch,hr,min,STORE_VAL=0,FLAG1=0,FLAG2=0;

unsigned int LDR_VAL1,LDR_VAL2,LDR_VAL3;

Lcd_Init(); // Initialize LCD

Lcd_Cmd(_LCD_CLEAR); // Clear display

Lcd_Cmd(_LCD_CURSOR_OFF);

delay();

delay();

Soft_I2C_Init();

delay();

rtc_init();

while(1)

{

Lcd_Out(1, 1, "TIME ");

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

delay();

Soft_I2C_Write(2);

Delay_100ms();

Soft_I2C_Start();

// Soft_I2C_Write(0xD0);

Soft_I2C_Write(0xD1);

ch=Soft_I2C_Read(0u);

Soft_I2C_Stop();

hr=ch;

display(ch);

delay();

delay();

delay();

Lcd_Chr_Cp(':');

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(1);

Delay_100ms();

Soft_I2C_Start();

//I2C1_Repeated_Start();

Soft_I2C_Write(0xD1);

ch=Soft_I2C_Read(0u);

min=ch;

delay();

Soft_I2C_Stop();

delay();

display(ch);

delay();

delay();

delay();

Lcd_Chr_Cp(':');

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(0);

Delay_100ms();

Soft_I2C_Start();

Soft_I2C_Write(0xD1);

ch=Soft_I2C_Read(0u);

Soft_I2C_Stop();

display(ch);

delay();

delay();

if(hr==0x12||hr==0x01||hr==0x02||hr==0x03||hr==0x04||hr==0x05||hr==0x06)

{

Lcd_Chr_Cp(' ');

Lcd_Chr_Cp('A');

Lcd_Chr_Cp('M');

}

else

{

Lcd_Chr_Cp(' ');

Lcd_Chr_Cp('P');

Lcd_Chr_Cp('M');

}

i=0;

Lcd_Out(2, 1, "DATE ");

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(4);

Delay_100ms();

Soft_I2C_Start();

Soft_I2C_Write(0xD1);

ch=Soft_I2C_Read(0u);

delay();

Soft_I2C_Stop();

display(ch);

delay();

delay();

Lcd_Chr_Cp('-');

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(5);

Delay_100ms();

Soft_I2C_Start();

Soft_I2C_Write(0xD1);

ch=Soft_I2C_Read(0u);

delay();

Soft_I2C_Stop();

display(ch);

delay();

delay();

Lcd_Chr_Cp('-');

Soft_I2C_Start();

Soft_I2C_Write(0xD0);

Soft_I2C_Write(6);

Delay_100ms();

Soft_I2C_Start();

Soft_I2C_Write(0xD1);

ch=Soft_I2C_Read(0u);

Soft_I2C_Stop();

display(ch);

delay();

delay();

}

}

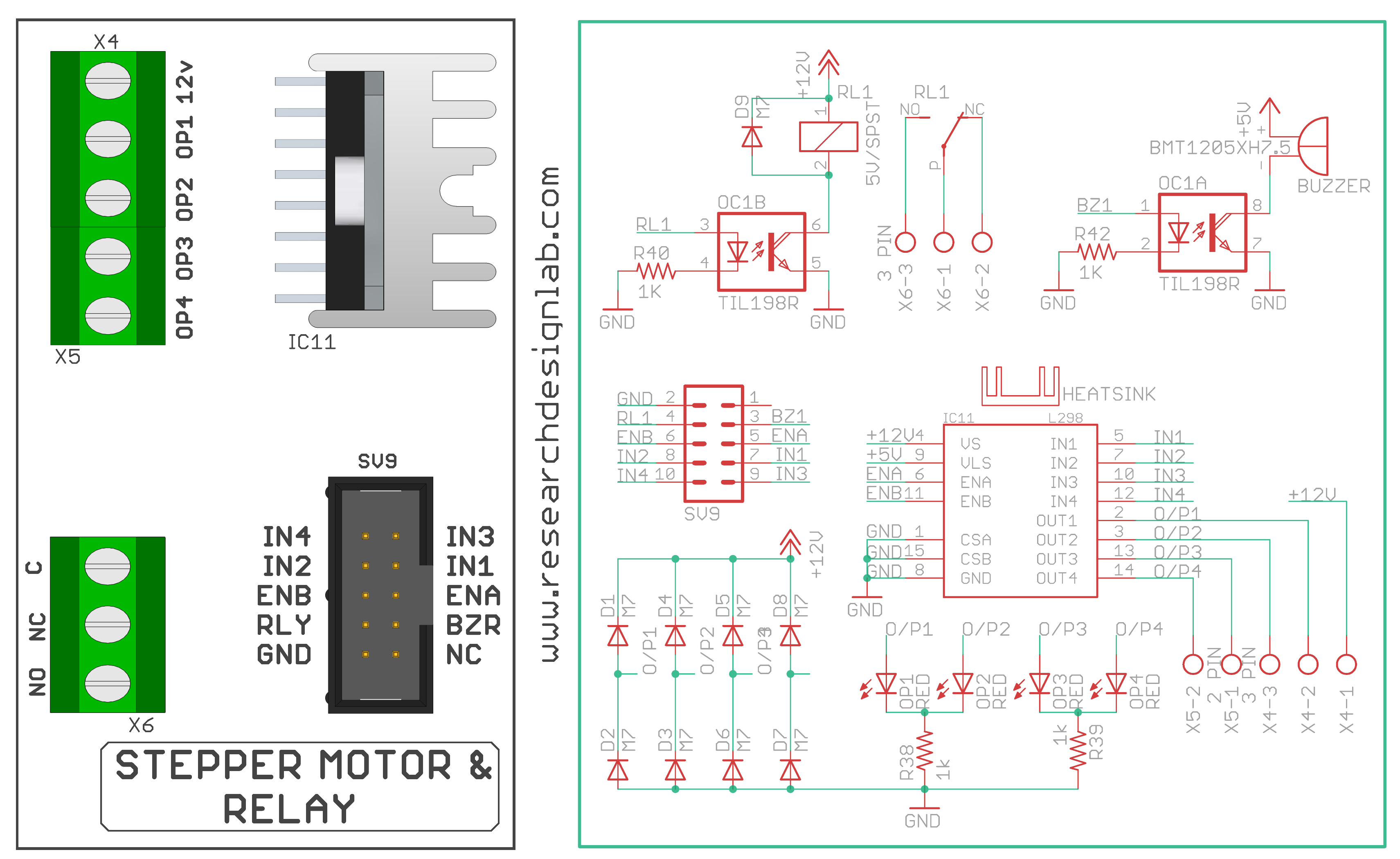

Buzzer

Aim:Interfacing Buzzer with PIC-Microcontroller.

Description:Turning ON and OFF the Buzzer after Particular delay.

Hardware Requirement: PIC Trainer Kit, Pickit2 Programmer,FRC cables,USB A to B cable and 12V 2A Adapter.

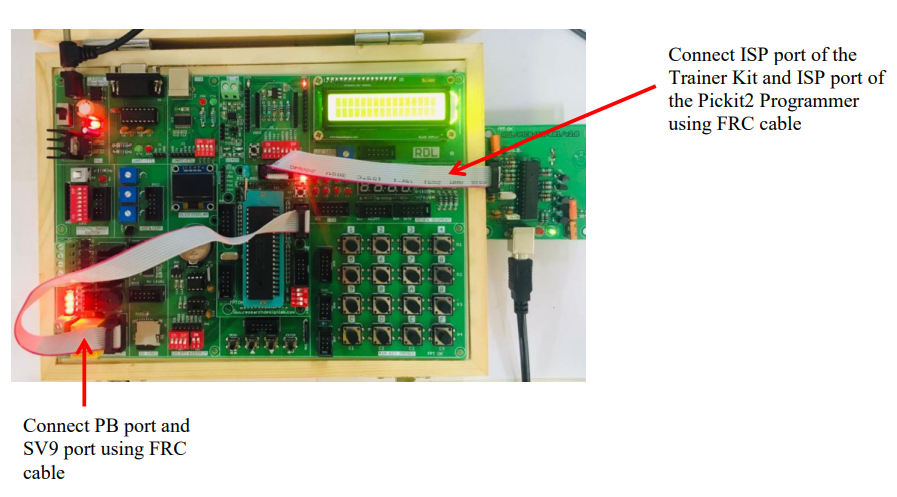

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC

cable

2. Connect PB port and SV9 port using FRC cable as shown above.

3. Connect the USB cable to the programmer and connect the Power Adapter to the PIC Trainer Kit.

4. Open MikroC Pro,write the program.Then click on Build to verify the code.

5.Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

6. Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller

and Buzzer will be turned ON and OFF.

Code

/*

* Project name:

PIC Development Board LED and Keypad code

* Copyright

(c) Researchdesignlab.com

* Test configuration:

MCU: PIC16F877A

Dev.Board: PIC

Oscillator: 20.0 MHz

Software: mikroC PRO for PIC v 4.6

Developer: DD

*/

sbit BUZZER at RB0_bit; //defining PortB Pin B0 as BUZZER

void main()

{

TRISB=0x00; //defining PORTB as output port

BUZZER= 1;

Delay_ms(1000);

BUZZER= 0;

Delay_ms(1000);

while(1)

{

BUZZER=1; //binary equivalent value:00000000

Delay_ms(1000);

BUZZER=0; //binary equivalent value:11111111

Delay_ms(1000);

}

}

Relay

Aim:Interfacing Relay with PIC-Microcontroller.

Description:Turning ON and OFF the Relay after Particular delay.

Hardware Requirement: PIC Trainer Kit, Pickit2 Programmer,FRC cables,USB A to B cable and 12V 2A Adapter

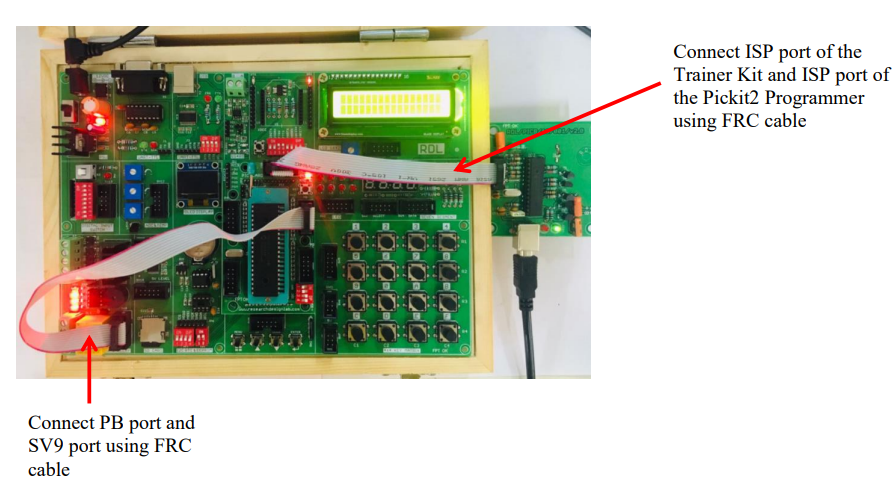

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC cable

2. Connect PB port and SV9 port using FRC cable as shown above.

3. Connect the USB cable to the programmer and connect the Power Adapter to the PIC Trainer Kit.

4. Open MikroC Pro,write the program.Then click on Build to verify the code

5. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

6. Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller and Relay will be turned ON and OFF.

Code

PIC Development Board LED and Keypad code

* Copyright

(c) Researchdesignlab.com

* Test configuration:

MCU: PIC16F877A

Dev.Board: PIC

Oscillator: 20.0 MHz

Software: mikroC PRO for PIC v 4.6

Developer: DD

*/

sbit RELAY at RB1_bit; //defining PortB Pin B1 as RELAY

void main()

{

TRISB=0x00; //defining PORTB as output port

RELAY= 1;

Delay_ms(1000);

RELAY= 0;

Delay_ms(1000);

while(1)

{

RELAY=1; //binary equivalent value:00000000

Delay_ms(1000);

RELAY=0; //binary equivalent value:11111111

Delay_ms(1000);

}

}

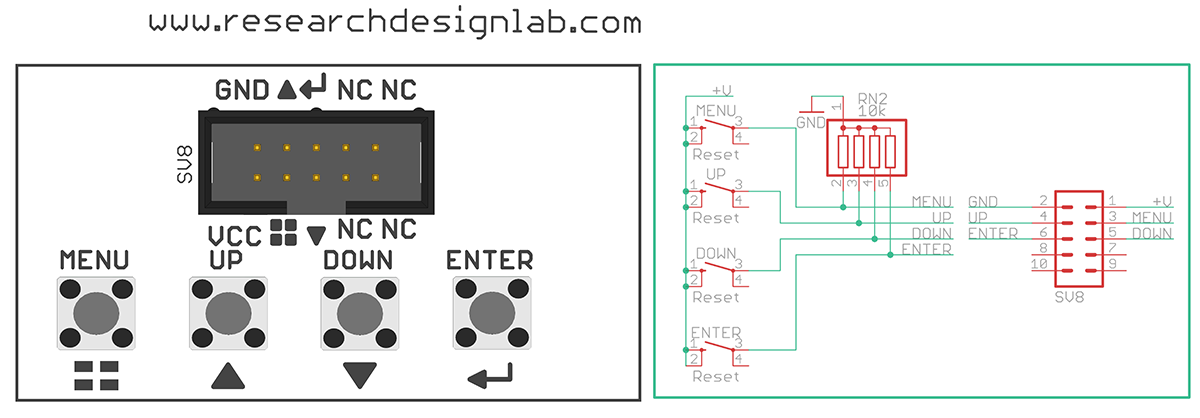

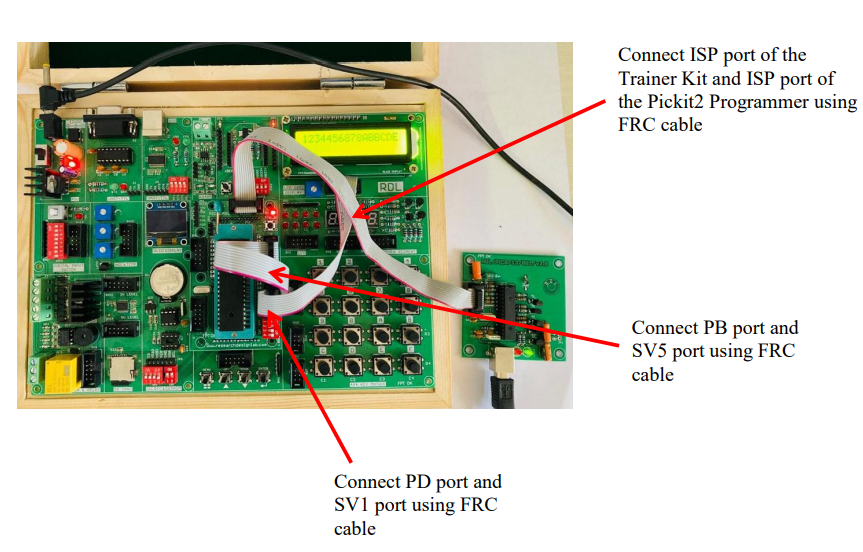

Hex Keypad

Aim:To interface 4x4 Hex keypad with PIC-Microcontroller.

Description:To display the pressed key on the LCD Display.

Hardware Requirement: PIC Trainer Kit, PicKit2 Programmer, FRC Cables, USB A to B Cable and 12V 2A Power Adapter.

Schematic Diagram

Procedure:

1. Connect ISP port of the Trainer Kit and ISP Port of the Pickit2 Programmer using FRC cable.

2. Connect PD port and SV5(4*4 Key Matrix) port and Connect PB port and SV1(LCD) port using FRC cable as shown above.

3.Connect the USB cable to the programmer and connect the 12V 2A Power Adapter to the PIC Trainer Kit.

4. Open MikroC Pro,write the program.Then click on Build to verify the code

5. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User Guide)

6. Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller

and Relay will be turned ON and OFF.

Code

sbit X_1 at RB0_bit;

sbit X_2 at RB1_bit;

sbit X_3 at RB2_bit;

sbit X_4 at RB3_bit;

sbit Y_1 at RB4_bit;

sbit Y_2 at RB5_bit;

sbit Y_3 at RB6_bit;

sbit Y_4 at RB7_bit;

#define Keypad_PORT PORTB

#define Keypad_PORT_Direction TRISB

// LCD module connections

sbit LCD_RS at RD0_bit;

sbit LCD_EN at RD1_bit;

sbit LCD_D4 at RD4_bit;

sbit LCD_D5 at RD5_bit;

sbit LCD_D6 at RD6_bit;

sbit LCD_D7 at RD7_bit;

sbit LCD_RS_Direction at TRISD0_bit;

sbit LCD_EN_Direction at TRISD1_bit;

sbit LCD_D4_Direction at TRISD4_bit;

sbit LCD_D5_Direction at TRISD5_bit;

sbit LCD_D6_Direction at TRISD6_bit;

sbit LCD_D7_Direction at TRISD7_bit;

// End LCD module connections

char keypad_scanner(void)

{

X_1 = 0; X_2 = 1; X_3 = 1; X_4 = 1;

if (Y_1 == 0) { delay_ms(100); while (Y_1==0); return '1'; }

if (Y_2 == 0) { delay_ms(100); while (Y_2==0); return '2'; }

if (Y_3 == 0) { delay_ms(100); while (Y_3==0); return '3'; }

if (Y_4 == 0) { delay_ms(100); while (Y_4==0); return '4'; }

X_1 = 1; X_2 = 0; X_3 = 1; X_4 = 1;

if (Y_1 == 0) { delay_ms(100); while (Y_1==0); return '4'; }

if (Y_2 == 0) { delay_ms(100); while (Y_2==0); return '5'; }

if (Y_3 == 0) { delay_ms(100); while (Y_3==0); return '6'; }

if (Y_4 == 0) { delay_ms(100); while (Y_4==0); return '8'; }

X_1 = 1; X_2 = 1; X_3 = 0; X_4 = 1;

if (Y_1 == 0) { delay_ms(100); while (Y_1==0); return '7'; }

if (Y_2 == 0) { delay_ms(100); while (Y_2==0); return '8'; }

if (Y_3 == 0) { delay_ms(100); while (Y_3==0); return 'A'; }

if (Y_4 == 0) { delay_ms(100); while (Y_4==0); return 'B'; }

X_1 = 1; X_2 = 1; X_3 = 1; X_4 = 0;

if (Y_1 == 0) { delay_ms(100); while (Y_1==0); return 'C'; }

if (Y_2 == 0) { delay_ms(100); while (Y_2==0); return 'D'; }

if (Y_3 == 0) { delay_ms(100); while (Y_3==0); return 'E'; }

if (Y_4 == 0) { delay_ms(100); while (Y_4==0); return 'F'; }

return 'n';

}

char switch_press_scan(void) // Get key from user

{

char key = 'n'; // Assume no key pressed

while(key=='n') // Wait untill a key is pressed

key = keypad_scanner(); // Scan the keys again and again

return key; //when key pressed then return its

value

}

void InitKeypad(void)

{

Keypad_PORT = 0x00; // Set Keypad port pin

values zero

Keypad_PORT_Direction = 0xF0; // Last 4 pins input, First 4

pins output

OPTION_REG &= 0x7F;

}

char Key;

void main()

{

Lcd_Init(); // Initialize LCD

Lcd_Cmd(_LCD_CLEAR);

InitKeypad();

while(1)

{

Key = switch_press_scan();

Lcd_Chr_Cp(Key);

}

}

DC Motor

Aim:To interface DC Motor with PIC-Microcontroller.

Description:To rotate DC Motor using Pic Microcontroller.

Hardware Requirement:PIC Trainer Kit, PicKit2 Programmer, DC Motor, FRC Cables, USB A to B Cable and 12V 2A

Power Adapter.

Procedure:

1. Connect ISP port of the Trainer Kit and ISP port of the Pickit2 Programmer using FRC cable.

2. Connect PB port and SV9 port using FRC cable as shown above.

3.Connect the DC Motor to Output Pins OP1 and OP2 of the Trainer Kit.

4. Connect the USB cable to the programmer and connect the 12V 2A Power Adapter to the PIC Trainer Kit.

5. Open MikroC Pro,write the program.Then click on Build to verify the code.

6. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User

Guide)

7.Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller

and you can see the DC Motor rotating.

Code

/*Oscillator: 20.0 MHz

Software: mikroC PRO for PIC v 4.6

Developer: DD

*/

sbit MOTOR1 at RB4_bit; //defining PortB Pin B4 as Motor1

sbit MOTOR2 at RB5_bit; //defining PortB Pin B5 as Motor2

void main()

{

TRISB=0x00; //defining PORTB as output port

MOTOR1=0;

MOTOR2=0;

Delay_ms(300);

while(1)

{

MOTOR1=1;

Delay_ms(1000);

MOTOR1=0;

Delay_ms(1000);

MOTOR2=1;

Delay_ms(1000);

MOTOR2=0;

Delay_ms(1000);

}

}

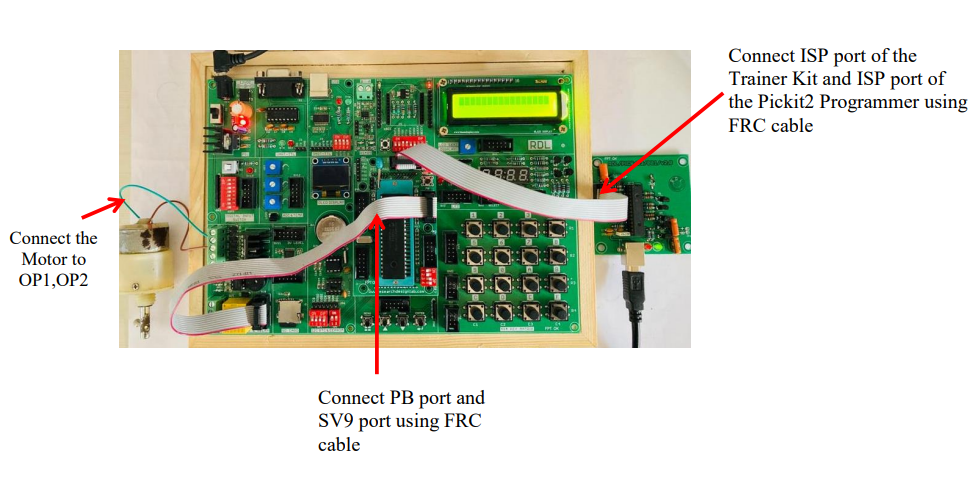

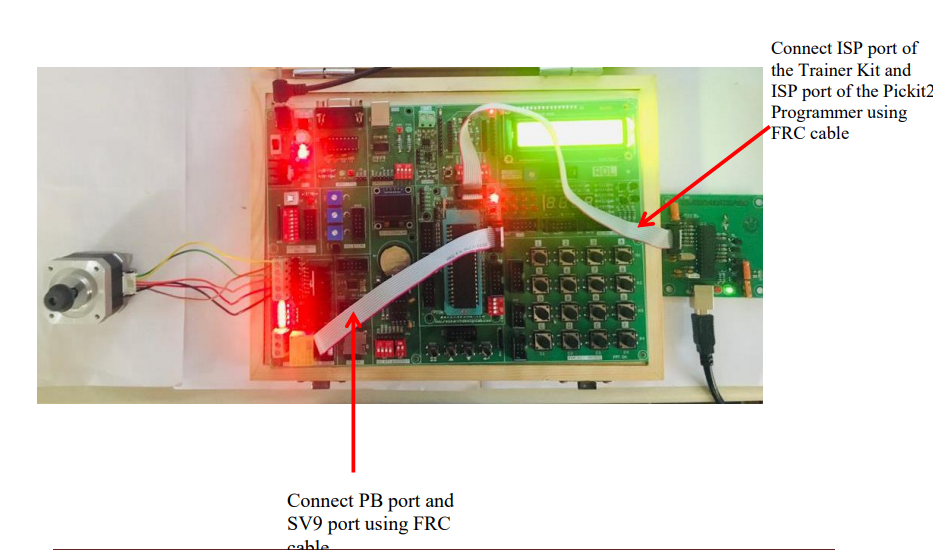

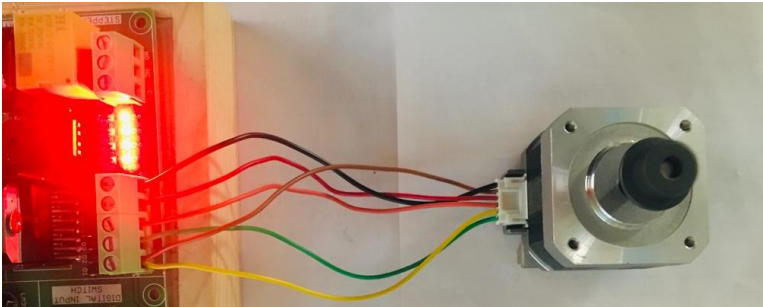

Stepper Motor

Aim:To interface Stepper Motor with PIC-Microcontroller.

Description:To rotate Stepper Motor using Pic Microcontroller.

Hardware Requirement:PIC Trainer Kit, PicKit2 Programmer, Stepper Motor, FRC Cables, USB A to B Cable and 12V

2A Power Adapter.

Schematic Diagram

1. Connect ISP port of the Trainer Kit and ISP port of the Pickit2 Programmer using FRC cable.

2. Connect PB port and SV9 port using FRC cable as shown above.

3.Connect the DC Motor to Output Pins OP1 and OP2 of the Trainer Kit.

4. Connect the USB cable to the programmer and connect the 12V 2A Power Adapter to the PIC Trainer Kit.

5. Open MikroC Pro,write the program.Then click on Build to verify the code.

6. Open Pickit2 Software to upload the hex File(Follow the steps given in the Pickit2 User

Guide)

7.Once the hex file is written successfully,Press the reset switch of the PIC Microcontroller and you can see Stepper Motor rotating Clockwise and Anti-Clockwise.

Code

int i=0;

void main()

{

TRISB=0X00;

PORTB=0X00;

while(1)

{

for(i=0;i<i++)

{

PORTB=0xEC;

Delay_ms(2);

PORTB=0xDC;

Delay_ms(2);

PORTB=0xBC;

Delay_ms(2);

PORTB=0x7C;

Delay_ms(2);

}

for(i=0;i<'100;i++)

{

PORTB=0x7C;

Delay_ms(2);

PORTB=0xBC;

Delay_ms(2);

PORTB=0xDC;

Delay_ms(2);

PORTB=0xEC;

Delay_ms(2);

}

}

}

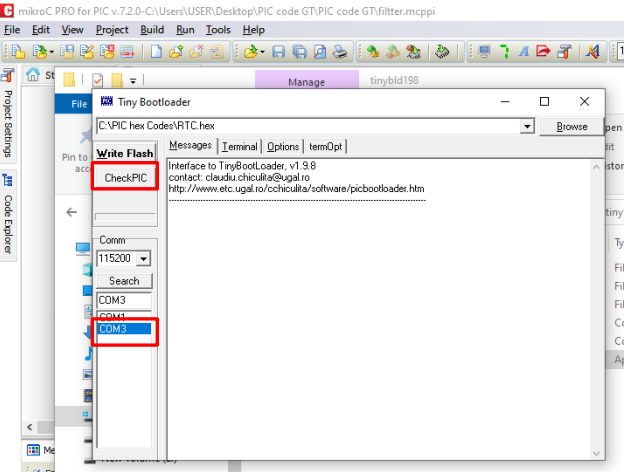

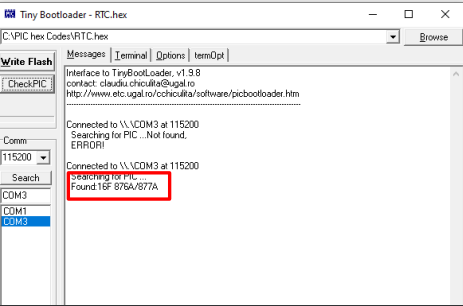

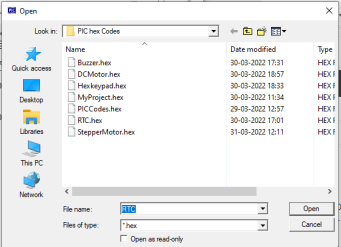

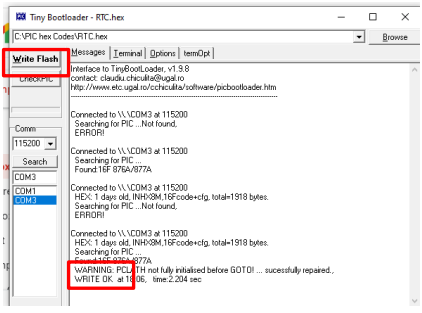

On Board Programming

Download and Install the Tiny PIC Bootloader,CLICK HERE

1. Once the Software gets Opened, Select your Com Port and click on Check PIC

2. Press the Reset switch of the PIC Controller

3.You will get the Notification as Found 16F877A

3.You will get the Notification as Found 16F877A

4.Browse your hex file(Ex:RTC) and click on Open

4.Browse your hex file(Ex:RTC) and click on Open

5.Click on Write Flash

5.Click on Write Flash

6.Press the Reset switch of the PIC Controller

7.You will get WRITE OK message.

Real Time Stamp Data (RTC)

• This program uses the CloudPLCRTC and Cloud_PLC libraries to log real-time data to an SD card.

• In the setup function, it initializes serial communication, creates a CSV file with a header, and sets up the RTC module.

• The loop function retrieves the current date and time from the RTC, prints it to the Serial Monitor, and appends the timestamp to the CSV file

every 3 seconds.

Schematic Diagram

Wiring Diagram

Code

#include "CloudPLCRTC.h"

#include "Cloud_PLC.h"

File myFile;

CloudPLCRTC rtc;

void setup()

{

Serial.begin(9600);

delay(1000);

Cloud_PLC_File_Init();

myFile = SD.open("/real_time_data.csv", FILE_WRITE);

if (myFile)

{

myFile.println(" Real Time DATA ");

myFile.close();

} else

{

Serial.println("error opening analog_data.csv");

}

rtc.begin();

// Uncomment the line below to set the RTC to the time this sketch was compiled

//rtc.adjustToCompileTime();

// Uncomment the line below to set the RTC to a specific date & time

//rtc.adjustToDateTime(2024, 7, 8, 17, 41, 10);

}

void loop()

{

String formattedDateTime = rtc.getFormattedDateTime();

Serial.println(formattedDateTime);

myFile = SD.open("/real_time_data.csv", FILE_APPEND);

if (myFile)

{

myFile.print(formattedDateTime);

delay(1000);

myFile.println();

myFile.close();

} else

{

Serial.println("error opening real_time_data.csv");

}

Serial.println();

delay(3000);

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

Digital Input WiFi Interface - JSON

• This program uses the Cloud_PLC library to connect to a WiFi network and send JSON data.

• In the setup function, it initializes serial communication, configures the WiFi connection, and sends an initial JSON payload.

• The loop function continuously checks the state of a digital input (IN1), prints its state to the Serial Monitor, and sends updated JSON data to

a specified URL every 2 seconds.

Wiring Diagram

Code

#include "Cloud_PLC.h" // Include the header file for Cloud_PLC library

void setup()

{

Serial.begin(115200);

// Initialize serial communication at 115200 baud rate

Cloud_PLC_initialisation();

Cloud_PLC_Config_WIFI("your SSID", "your password");

Serial.println("Connecting to WiFi..."); // Call the initialization function for Cloud_PLC

Serial.println("Sending initial JSON data...");

Cloud_PLC_JSON("URL", "state", "Initial State");

Serial.println("Initial JSON data sent!");

}

void loop()

{

// Check the digital input state of DI1

const char* inputState;

if (Cloud_PLC_Digital_Read(DI1) == HIGH)

{

inputState = "HIGH";

} else

{

inputState = "LOW";

}

// Print the digital input state to the Serial Monitor

Serial.println(inputState);

// Send the JSON data

Cloud_PLC_JSON("https://yourURL.com/CloudplcTest.php", "DIN", inputState);

delay(2000); // Wait for 2000 milliseconds (2 seconds)

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

Digital Input WiFi Interface - MQTT

• This program uses the Cloud_PLC library to connect to WiFi and configure MQTT communication.

• In the setup function, it initializes serial communication, sets up WiFi, and configures MQTT with provided credentials.

• The loop function checks the state of a digital input (IN1), prints the state to the Serial Monitor, and publishes the state to an MQTT topic

every 2 seconds.

Wiring Diagram

Code

#include "Cloud_PLC.h" // Include the header file for Cloud_PLC library

void setup()

{

Serial.begin(115200);

delay(500);

// Initialize serial communication at 115200 baud rate

Cloud_PLC_initialisation();

Serial.println("Configuring to WiFi..."); // Call the initialization function for Cloud_PLC

Cloud_PLC_Config_WIFI("your SSID", "your password");

Serial.println("Configuring MQTT...");

Cloud_PLC_Config_MQTT("yourMQTT_brocker_address", PORT, "username", "password");

delay(1000);

}

void loop()

{

// Check the digital input state of DI1

const char* inputState;

if (Cloud_PLC_Digital_Read(DI1) == HIGH)

{

inputState = "HIGH";

} else

{

inputState = "LOW";

}

// Print the digital input state to the Serial Monitor

Serial.println(inputState);

Cloud_PLC_MQTT_Publish("DIN", inputState);

delay(2000); // Wait for 2000 milliseconds (2 seconds)

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

Controlling Relay By MQTT

• This program connects an Cloud PLC to a Wi-Fi network and an MQTT broker, allowing it to receive commands to control two relays via

MQTT messages.

• The relays are connected to pins 15 and 13 and can be turned on or off by publishing specific messages ("1N" or "1F" for Relay 1, "2N" or

"2F" for Relay 2) to the subscribed topic "CPLRelay."

• The ESP32 maintains the connection to the MQTT broker and handles incoming messages to control the relays accordingly.

Wiring Diagram

Code

#include <WiFi.h>

#include <PubSubClient.h>

// Replace these with your network credentials and MQTT details

const char* ssid = "your ssid";

const char* password = "your password";

const char* mqtt_server = "MQTT brocker address";

const int mqtt_port = your PORT number;

const char* mqtt_user = "your MQTT username";

const char* mqtt_password = "your password";

const char* subscribe_topic = "CPLRelay";

WiFiClient espClient;

PubSubClient client(espClient);

// Function to connect to WiFi

void setup_wifi() {

Serial.print("Connecting to ");

Serial.println(ssid);

WiFi.begin(ssid, password);

while (WiFi.status() != WL_CONNECTED)

{

delay(500);

Serial.print(".");

}

Serial.println("\nWiFi connected. IP address: ");

Serial.println(WiFi.localIP());

}

// Callback function for when a message is received

void callback(char* topic, byte* message, unsigned int length)

{

Serial.print("Message arrived on topic: ");

Serial.print(topic);

Serial.print(". Message: ");

String messageString;

for (int i = 0; i < length; i++)

{

messageString += (char)message[i];

}

Serial.println(messageString);

// Control relays based on the message

if (messageString.equals("1N"))

{

digitalWrite(15, HIGH);

} else if (messageString.equals("1F")) {

digitalWrite(15, LOW);

} else if (messageString.equals("2N")) {

digitalWrite(13, HIGH);

} else if (messageString.equals("2F")) {

digitalWrite(13, LOW);

}

}

// Function to reconnect to MQTT broker

void reconnect()

{

while (!client.connected())

{

Serial.print("Attempting MQTT connection...");

if (client.connect("ESP32Client", mqtt_user, mqtt_password))

{

Serial.println("connected");

client.subscribe(subscribe_topic);

} else {

Serial.print("failed, rc=");

Serial.print(client.state());

Serial.println(" try again in 5 seconds");

delay(5000);

}

}

}

void setup()

{

Serial.begin(115200);

pinMode(15, OUTPUT);

pinMode(13, OUTPUT);

digitalWrite(15, LOW);

digitalWrite(13, LOW);

setup_wifi();

client.setServer(mqtt_server, mqtt_port);

client.setCallback(callback);

}

void loop()

{

if (!client.connected())

{

reconnect();

}

client.loop();

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

Controlling Relay Using WiFi AP

• This code configures the Cloud PLC as a Wi-Fi access point and sets up a web server listening on port 80.

• When a client connects and sends an HTTP request, the server reads the request and checks if it contains "ON" or "OFF" to control a relay

through the Cloud_PLC_Relay_state function.

• The server responds with the relay's status and closes the connection after handling the request

• The access point's IP address is printed to the serial monitor for client connection.

Wiring Diagram

Code

#include "Cloud_PLC.h"

#include <WiFi.h>

const char* apSSID = "your ssid"; //your SSID

const char* apPassword = "your password"; //Your PASSWORD

WiFiServer server(80);

void setup()

{

Serial.begin(115200);

setupAccessPoint(); // Set up ESP32 as an access point Cloud_PLC_initialisation();

// Initialize the Cloud PLC library

server.begin(); // Start the server

Serial.println("Server started");

}

void loop()

{

WiFiClient client = server.available(); // Check if a client has connected

if (client)

{

while (client.connected() && !client.available())

{ // Wait for data from the client

delay(1);

}

String request = client.readStringUntil('\r'); // Read the first line of the request

Serial.println(request);

if (request.indexOf("ON") != -1)

{ // Process the request

Cloud_PLC_Relay_state(0, HIGH); // Turn on Relay

client.println("Relay turned ON");

} else if (request.indexOf("OFF") != -1)

{

Cloud_PLC_Relay_state(0, LOW); // Turn off Relay

client.println("Relay turned OFF");

} else

{

client.println("Invalid command");

}

// Close the connection

client.stop();

}

}

void setupAccessPoint()

{

WiFi.softAP(apSSID, apPassword); // Set up the ESP32 as an access point

delay(100);

Serial.println("Access Point IP Address: " + WiFi.softAPIP().toString());

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

Digital Input Interface - Bluetooth

• This program uses the Cloud_PLC library and Bluetooth Serial to monitor a digital input (IN1) and communicate its state.

• In the setup function, it initializes serial communication for both the Serial Monitor and Bluetooth, allowing pairing with the Bluetooth device

named "Cloud_PLC."

• The loop function checks if IN1 is HIGH or LOW, prints the state to both the Serial Monitor and a paired Bluetooth device, and updates every

500 milliseconds.

Code

#include "Cloud_PLC.h"

#include "BluetoothSerial.h"

//Include the header file for Cloud_PLC library

BluetoothSerial SerialBT;

void setup()

{

Serial.begin(115200);

SerialBT.begin("Cloud_PLC");

Serial.print("The device started, Now you can pair it with bluetooth");

//Initialize serial communication at 115200 baud rate

Cloud_PLC_initialisation();

//Call the initialization function for Cloud_PLC

}

void loop()

{

// Check the digital input state of DI1

if (Cloud_PLC_Digital_Read(DI1) == HIGH) //input channel, IN1,IN2,IN3,IN4,IN4

{

Serial.println("HIGH");

SerialBT.println("HIGH");

// Print "ON" to the Serial Monitor if IN1 is HIGH

delay(500);

}

else

{

Serial.println("LOW");

SerialBT.println("LOW"); // Print "OFF" to the Serial Monitor if IN1 is not

delay(500);

// Wait for 2000 milliseconds (2 seconds)

}

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

Controlling Relay By Bluetooth

• This code sets up an Cloud PLC to control two relays via Bluetooth.

• It initializes the relays as outputs and starts Bluetooth communication with a device name "CPL_Relays."

• In the loop function, it listens for incoming Bluetooth commands to control the relays: "ON1" and "OFF1" for Relay 1, and "ON2" and

"OFF2" for Relay 2. It also provides feedback over Bluetooth and prints received commands for debugging.

Code

#include <BluetoothSerial.h>

// Define the relay pins

#define RELAY1_PIN 15

#define RELAY2_PIN 13

// Create a BluetoothSerial object

BluetoothSerial SerialBT;

void setup()

{

// Initialize serial communication for debugging

Serial.begin(115200);

// Initialize the relay pins as outputs

pinMode(RELAY1_PIN, OUTPUT);

pinMode(RELAY2_PIN, OUTPUT);

// Set the relays to be off initially

digitalWrite(RELAY1_PIN, LOW);

digitalWrite(RELAY2_PIN, LOW);

// Begin serial communication over Bluetooth

SerialBT.begin("CPL_Relays"); // Bluetooth device name

Serial.println("Bluetooth device started, you can now pair it with Bluetooth!");

}

void loop()

{

// Check if data is available on the Bluetooth serial

if (SerialBT.available())

{

// Read the incoming string

String request = SerialBT.readStringUntil('\n');

// Print the received string to the Serial Monitor (for debugging)

Serial.print("Received: ");

Serial.println(request);

// Control the relays based on the received command

if (request.indexOf("ON1") != -1)

{

digitalWrite(RELAY1_PIN, HIGH); // Turn Relay 1 on

SerialBT.println("Relay 1 turned ON");

}

else if (request.indexOf("OFF1") != -1)

{

digitalWrite(RELAY1_PIN, LOW); // Turn Relay 1 off

SerialBT.println("Relay 1 turned OFF");

}

else if (request.indexOf("ON2") != -1)

{

digitalWrite(RELAY2_PIN, HIGH); // Turn Relay 2 on

SerialBT.println("Relay 2 turned ON");

}

else if (request.indexOf("OFF2") != -1)

{

digitalWrite(RELAY2_PIN, LOW); // Turn Relay 2 off

SerialBT.println("Relay 2 turned OFF");

}

else

{

SerialBT.println("Invalid command");

}

}

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

Embedded Webserver

• This program sets up a web server using a Cloud PLC to control two relays through a web interface.

• In the setup function, it initializes serial communication, connects to Wi-Fi, and starts the web server.

• The loop function listens for incoming HTTP requests, parses them to control the relays based on the URL path, and serves a simple HTML

page to control the relays.

• It updates the relay states and serves the appropriate HTML based on user interactions with the web page.

Wiring Diagram

Code

#include <Cloud_PLC.h>

WiFiServer server(80); // Set web server port number to 80

String header; // Variable to store the HTTP request

const int relayPin1 = 15; // Relay pins

const int relayPin2 = 13; // Relay pins

String relayState1 = "OFF"; // Current state of the relays

String relayState2 = "OFF";

void setup()

{

Serial.begin(115200);

pinMode(relayPin1, OUTPUT); // Initialize the relay pins as outputs

pinMode(relayPin2, OUTPUT);

digitalWrite(relayPin1, LOW);

digitalWrite(relayPin2, LOW);

Cloud_PLC_Config_WIFI("TEST", "12345678"); // Connect to Wi-Fi network

server.begin(); // Start the server

}

void loop()

{

WiFiClient client = server.available(); // Listen for incoming clients

if (client)

{ // If a new client connects,

Serial.println("New Client."); // Print a message out in the serial port

String currentLine = ""; // Make a String to hold incoming data from the client

while (client.connected())

{ // Loop while the client's connected

if (client.available())

{ // If there's bytes to read from the client,

char c = client.read(); // Read a byte, then

Serial.write(c); // Print it out the serial monitor

header += c;

if (c == '\n')

{ // If the byte is a newline character

if (currentLine.length() == 0)

{ // If the current line is blank, you got two newline characters in a row.

// That's the end of the client HTTP request, so send a response:

client.println("HTTP/1.1 200 OK");

client.println("Content-type:text/html");

client.println("Connection: close");

client.println();

// Display the HTML web page

client.println("<!DOCTYPE html><html>");

client.println("<head><meta name=\"viewport\" content=\"width=device-width, initial-scale=1\">");

client.println("<link rel=\"icon\" href=\"data:,\">");

client.println("<style>body { text-align: center; font-family: Arial; } .button { background-color: #4CAF50; border: none; color: white; padding: 15px 32px; text-align: center; text-decoration: none; display: inline-block; font-size: 16px; margin: 4px 2px; cursor: pointer; } .button2 {background-color: #ff0000;}</style></head>");

client.println("<body><h1>Cloud PLC Relay Control</h1>");

client.println("<p>Relay 1 - State " + relayState1 + "</p>");

if (relayState1 == "OFF")

{

client.println("<p><a href=\"/relay1/on\"><button class=\"button\">ON</button></a></p>");

} else

{

client.println("<p><a href=\"/relay1/off\"><button class=\"button button2\">OFF</button></a></p>");

}

client.println("<p>Relay 2 - State " + relayState2 + "</p>");

if (relayState2 == "OFF")

{

client.println("<p><a href=\"/relay2/on\"><button class=\"button\">ON</button></a></p>");

} else

{

client.println("<p><a href=\"/relay2/off\"><button class=\"button button2\">OFF</button></a></p>");

}

client.println("</body></html>");

client.println(); // The HTTP response ends with another blank line

break; // Break out of the while loop

}

else

{ // If you got a newline, then clear currentLine

currentLine = "";

}

}

else if (c != '\r')

{ // If you got anything else but a carriage return character,

currentLine += c; // Add it to the end of the currentLine

}

// Check if the client request is to turn relay 1 on or off

if (header.indexOf("GET /relay1/on") >= 0)

{

relayState1 = "ON";

digitalWrite(relayPin1, HIGH);

} else if (header.indexOf("GET /relay1/off") >= 0)

{

relayState1 = "OFF";

digitalWrite(relayPin1, LOW);

}

// Check if the client request is to turn relay 2 on or off

if (header.indexOf("GET /relay2/on") >= 0)

{

relayState2 = "ON";

digitalWrite(relayPin2, HIGH);

} else if (header.indexOf("GET /relay2/off") >= 0)

{

relayState2 = "OFF";

digitalWrite(relayPin2, LOW);

}

}

}

// Clear the header variable

header = "";

client.stop(); // Close the connection

Serial.println("Client disconnected.");

Serial.println("");

}

}

Note

![]() Libraries, User Manuals and Installation guides look into the download section.

Libraries, User Manuals and Installation guides look into the download section.

![]() Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

Install the Cloud PLC libraries(cloudplc.h) before getting start with coding. Download

![]() Above download link, you will find all the IO functionalities included in the Cloud PLC library.

Above download link, you will find all the IO functionalities included in the Cloud PLC library.

![]() In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.

In the Arduino IDE, go to the Boards Manager, select the ESP32 board, and ensure that you have selected the board version is 1.0.4.