FEATURES

- Plug & Play Interface Connectivity.

- Professional EMI/RFI Complaint PCB Layout Design.

- Modular Block design makes Easy access & quick Prototyping.

- FRC connectivity features minimize the connection Error.

- ROHS Compliant High Quality Grade PCB.

- Supported DC 12V Power Supply.

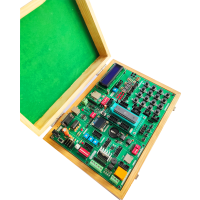

- Wooden Enclosure - Go green initiative.

- This kit can easily interface with other RDL Development Training kits.

- 2 nos stepper motors with driver interface.

- 2 nos DC Motors with driver interface.

- 2 nos Servo motors.

- 4 channel 8 Amps Relay.

- 1 nos Electromagnetic actuators / EM Lock with Relay.

- 1 no Industrial IR Proximity Sensor.

- 1 channel ADC converter ADC08801.

- 1x Analog Test POT.

- Overcurrent protection Fuse.

APPLICATION

- Automation

- Robotics

- Exoskeleton

- Human Robotic Interface

- Valve Control

- Motion & Direction Control Application

- Access Control gate

- Humanoid

SCOPE OF LEARNING EXPERIMENTS

- Interface DC motor and control the speed and direction.

- Interface Stepper Motor and control the Step , speed and Direction.

- Interface Servo motor and control the direction.

- Interface Relay and control the appliance ON / OFF.

- Interface the Temperature sensor to ADC and control the relay.

- Sense the proximity object and control the Stepper motor.

- Sense the Proximity object and control the Electromagnetic lock.

- Sense proximity object and control the dc motor.

- Control the Servo motor using PWM technique.

- Sense the proximity object and controlling the servo motor angle.

SPECIFICATION

- IR Proximity Sensor

- Power supply: 5V.

- Current: 3 - 4mA.

- Range: 3 – 80cm adjustable.

100 RPM BO Motor

- Operating Voltage(VDC): 3~12

- Shaft Length (mm): 8.5

- Shaft Diameter (mm): 5.5 (Double D-type)

- No Load Current: 40-180mA.

- Rated Speed(After Reduction): 100 RPM

- Rated Torque: 1 Kg Cm

ADC0804 IC

- 0-V to 5-V Analog Input Voltage Range With Single 5-V Supply.

- No Zero Adjust Required.

- Resolution: 8 Bits.

- Total Error: ±1/4 LSB, ±1/2 LSB and ±1 LSB.

- Conversion Time: 100 µs.

L293D DC MOTOR DRIVER:

- Motor Supply Voltage selection: 5 V or 12 V.

- Separate Input-Logic Supply.

- Output Current 600mA Per Channel.

- Output Clamp Diodes for Inductive Transient Suppression.

- Internal ESD Protection.

STEPPER MOTOR

- Rated voltage: 5V DC.

- Reduction Ratio: 64:1.

- Step Angle: 5.625° /64.

- Frequency: 100Hz.

- Self-positioning Torque: >34.3mN.m.

- Friction torque: 600-1200 gf.cm.

- Pull in torque: 300 gf.cm.

STEPPER MOTOR DRIVER

- Using ULN2803 2 Stepper motors can be driven.

POWER SUPPLY

- 12VDC input with Fuse & Fuse blown LED indicator.

- On board Buck Convertor.

RELAYS

- 4X 12VDC relays with 6A 230VAC

DC 12V ELECTRIC DOOR LOCK

- Holding force: 0.25 kg

- Energized forms: intermittent

- Unlocking time: 1s

SUPPLY VOLTAGE

- Supply Input Voltage DC 12V / 24V

- Permissible Range, Lower Limit (DC) 9V

DIMENSION

- Wooden Box : 247mm X 170mm X 60mm

ORDER CODE: RDL887